Micro-, nano- and quantum technology infrastructure

Advanced micro- and nanoelectronics along with photonics and quantum technologies are at the core of tomorrow’s technology. VTT’s world-class technology infrastructure enables material development, device development, concept creation, innovation, design, prototyping, piloting, fabrication and characterisation of micro- and nanoelectronic components.

At VTT, we are our customers’ partners from the early innovation stage all the way to small-scale manufacturing and technology transfer. Our experts help you develop next-generation solutions and bring them to market. Our IP is available for licensing, and we have a wide network of collaboration companies to support technology transfer to high volume production as well as capabilities to integrate software and AI to products.

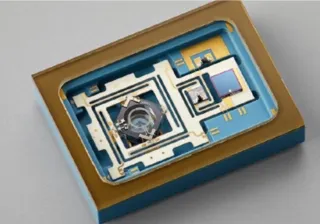

VTT’s micro- and nanoelectronics technology infrastructure supports the entire research and development cycle of technologies such integrated photonics, MEMS, quantum, superconducting technologies, 3D integration, post-CMOS processing, 2D materials, RF, piezo materials as well as semiconductor technologies. Our processing capabilities also allow you to make material development for specific applications.

Our key infrastructure

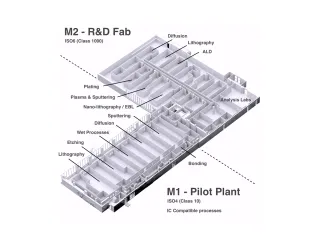

- Our technology infrastructure is located in Micronova, Espoo, and the coming Kvanttinova hub.

- We support 200 mm wafer size, and in the future we will have 300 mm capabilities.

- VTT’s microelectronics cleanroom in Micronova is currently the largest R&D cleanroom in the Nordic countries.

- In-house processing capabilities for semiconducting, integrated photonics, MEMS, post-CMOS, quantum and superconducting technologies.

- Extensive sensor development and characterisation laboratories, along with photonics and optics characterisation laboratories.

- Cryogenic characterisation laboratories for the characterisation of superconducting devices and wafer level cryogenic probing.

- ESA external laboratory on millimeter wave technologies, MilliLab.

- We support wafer-level testing and probing facilities.

Cleanroom characteristics

Micronova cleanroom holds the ISO 9001:2015 certification for research and development work and pilot manufacturing for devices for micro-, nano-, photonics and quantum technology applications, wafer processing services and facility maintenance.

Micronova’s cleanroom is run by dedicated maintenance, process engineering, quality and cleanroom operations professionals.

- Total Area 2,600 m2

- Cleanroom Classification ISO 4…ISO 6

- Temperature 21 °C ± 0,5 °C

- Relative humidity 45 % ± 5

- Clean bay – Service chase type

- Raised perforated floor

- Subfab with technical support areas

Micronova processing capabilities in 200 mm

Lithography

- i-line stepper, 5:1, 0.35 µm CD

- DUV KrF stepper, 150 nm CD*

- Automatic CD and defect measurement

- CD-SEM 200/300 mm*

- Contact/proximity aligners

Etching

- Polysilicon/nitride

- Oxide; thin film and advanced oxide etching

- Metals; Al, Mo, Ti-W, Nb (TCP)

- Oxide + metal etch 200 mm*

- Deep silicon etching

- Anhydrous HF vapour

- XeF2 etching

- Ion trimming

- Wet etching, various

Deposition

Seven sputtering tools and multiple evaporators; wide range of materials incl. Al, Ti, TiW, W, AlN, ScAlN, Au, Ag

- Additional sputter tools for 200 mm*

- LPCVD of nitride, poly, and oxide (TEOS, LTO)

- PECVD; nitride and oxide

- 200 mm PECVD M2

- ALD: aluminium oxide, titanium oxide, hafnium oxide, zinc oxide, zirconium oxide, TiN, AlN, etc.

- Parylene

Epitaxy

- Silicon and Germanium selective epitaxy*

- MOCVD

Ion implantation

- Medium-current ion implanter; n- or p-type doping of silicon*

Plating, spin-coating

- Cu (via or wiring), Ni, Sn-Ag, Sn-Pb, In-Sn, Au (automated plating stations 200mm)*

- Polyimide

Annealing

- RTA and annealing in different atmospheres

3D integration

- CMP of Si/oxide 200 mm

- Cu CMP 200 mm for TSV and damascene*

- Direct wafer bonding, fusion and thermal compression

- Silicon backgrinding

- Cu TSV grinding*

- Ion trimming

Backend

- Dicing, flip-chip and wire bonding, pick and place

Characterisation

- Various inline and offline characterisation tools, device parameter analyser, network analyser

*) Coming in 2026–2028 through funding from Chips Act Pilot Line projects FAMES, APECS, PIXEurope and NanoIC and Ministry of Economic Affairs and Employment.

We provide:

- Research and development services from concepting to design, prototyping, piloting, fabrication and characterisation

- Application-specific material development

- Heterogeneous integration and wafer-level packaging solutions

- Our facilities in Oulu also support LTCC packaging for RF and photonics applications

- Large IPR portfolio

For:

- Product companies

- Small- and medium sized companies, start-ups, spin-offs

- Semiconductor suppliers

- Semiconductor equipment makers

- Electronics industry

- Telecom industry

- Space & defence industry

- Medical industry