Sustainable structural materials to improve durability, circularity and performance

Structural materials are fundamental to the sustainability and resilience of our built environment. Achieving low-carbon and resource-efficient construction requires solutions that improve the durability, circularity and performance of concrete, steel and engineered wood. At the same time, safety and structural resilience must remain uncompromised. VTT supports this shift by developing, characterising and validating new sustainable structural materials and solutions, and by ensuring the performance of existing structures in demanding environments.

Key facts about sustainable structural materials

Construction materials are a significant source of greenhouse gas emissions. VTT develops and validates low-carbon, durable and sustainable structural materials for buildings and infrastructure.

Our expertise covers the full lifecycle of structural materials – from material selection, design and modelling to quality assessment, reuse, recycling and service-life extension.

By combining scientific research and industry-scale validation, we help the construction industry meet safety, resilience, durability and sustainability targets for concrete, steel and wood structures.

The role of structural materials in low-carbon and circular construction

Construction materials are responsible for around 11% of global energy-related CO2 emissions. The construction and demolition sector also generates roughly one-third of the world’s solid waste, largely due to limited material circularity.

Developing sustainable structural materials and improving their longevity and reuse potential reduces the environmental footprint of construction and accelerates the shift toward carbon neutrality.

This is where VTT plays a central role. We carry out applied research, development and innovation to make structural materials more sustainable, durable and circular. Our work covers cementitious materials, structural steels and engineered wood, helping industry and infrastructure owners improve performance and reduce environmental impact.

Evaluating material behaviour and performance in demanding conditions

Structural materials must withstand decades of mechanical loads as well as environmental loads, such as thermal and chemical exposure. VTT studies their performance under demanding conditions, including marine or harsh groundwater environments, extreme cold, temperature fluctuations and seismic hazards such as earthquakes. This knowledge helps industry make reliable material choices, design safer structures and predict long-term performance.

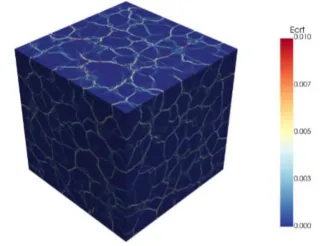

We combine materials science, material characterisation, multiscale modelling, laboratory testing and field validation to develop new material solutions and assess the performance of existing ones. We model material behaviour from the atomistic scale to the structural level, linking microscopic phenomena to macroscopic performance.

We help the construction industry and infrastructure owners:

Lower material emissions by developing and testing low-carbon concretes, steels and renewable alternatives.

Predict durability and service life using experimental testing, data analysis and advanced modelling.

Accelerate material development and decision-making by combining state-of-the-art material models with advanced testing facilities.

Ensure the safety and resilience of structures and infrastructure portfolios.

Validate new material concepts and components virtually or under realistic conditions in our research and pilot environments.

Enable circular construction through methods that support reuse, recycling and material traceability.

Make research-based decisions and define the right material specifications and performance requirements for each case or infrastructure.

Why partner with VTT

VTT combines multidisciplinary expertise with a deep understanding of material behaviour in demanding environments. We address challenges that lack ready-made solutions and develop new tools, models and testing methods when existing approaches are not sufficient.

Our multidisciplinary approach opens new possibilities across structural material applications. The following examples illustrate how we turn scientific insight into practice.

Reducing emissions through low-carbon concrete

Concrete and other cementitious materials are the backbone of construction but also among the most carbon-intensive ones. Portland cement production alone is responsible for about 7–8% of global CO2 emissions, making it one of the largest single industrial sources of greenhouse gases.

Reducing the carbon footprint of concrete starts with lowering the amount of cement and virgin raw materials used in production. Even partial replacement of cement or aggregates can significantly cut emissions.

VTT develops low-carbon cement and sustainable concrete. We explore how alternative binders, industrial side streams and recycled materials (e.g. aggregates) can replace conventional ingredients without compromising strength and long-term performance.

Our research focuses on optimising material compositions to cut emissions while maintaining the mechanical and durability performance required for long-lasting concrete structures.

Our spin-off Carbonaide has a solution for manufacturing carbon-negative concrete by combining efficient carbonation during curing with low-carbon binders.

Concrete designed for demanding environments

Beyond reducing embodied carbon, concrete structures must also meet stringent durability requirements. We study the long-term performance of concrete in demanding conditions where mechanical loads, moisture, temperature variations and chemically aggressive environments accelerate degradation. Some examples include:

Offshore wind turbine foundations and hydropower dams – constantly exposed to chemically aggressive environments or extreme weather.

Underground heat storage systems – subjected to the combined effects of hydrostatic pressures, elevated temperatures, prolonged thermal cycling and potentially chemically aggressive groundwater exposure that challenge material integrity.

Nuclear waste repositories – where materials must remain stable and prevent the release of radionuclides over exceptionally long timescales.

Sustainable steel construction

Steel is another essential structural material in modern construction. However, global constructional steel production remains highly carbon-intensive and accounts for around 4–6% of global CO₂ emissions.

As steel is already recycled at high rates, VTT focuses on extending its service life and enabling reuse without melting the material. This approach can reduce steel’s carbon footprint by 90%.

We develop new structural applications and circular solutions for carbon steel and stainless steel, including testing protocols and assessment methodologies for reused materials.

Our research and testing cover the performance and durability of steel structures, including studies on corrosion, ageing, reusability and recyclability. With decades of experience in the structural use of stainless steels in harsh environments, we help ensure long service life in demanding conditions.

Supporting the use of engineered wood in construction

Engineered wood products, such as cross-laminated timber (CLT), glulam and sawn timber, provide renewable, low-carbon alternatives for certain structural applications.

We study how moisture and temperature affect stresses, deformations, cracking and decay over time. By combining testing, real-time monitoring, numerical modelling and service life prediction, we help assess and improve the durability and reliability of wooden structures in different environments.

Circularity and reuse of construction materials

Our work also advances traceability and material data management to support the circular use of structural materials. We develop and apply methods to assess, qualify and enable the reuse of these materials. This includes testing materials recovered from existing buildings and infrastructure, analysing their properties and defining the requirements for future materials to improve their reuse potential.

Turning construction and demolition waste into valuable resources helps lower emissions while securing access to sustainable raw materials in the future. Circularity also depends on the careful design of today’s structures – they must be made of low-impact materials, be durable, safe and resilient, and remain adaptable to future use scenarios.

Who we work with

We collaborate across the entire lifecycle of construction materials, buildings and infrastructure – from early design and material development to the reuse and recycling of structures at the end of their service life. We work with:

Building designers, consultants and construction companies – to provide knowledge, guidance and tools for the early design and planning phase, modelling material behaviour and predicting long-term performance.

Material producers – to develop and validate new, low-carbon and durable materials for demanding and load-bearing applications.

Component manufacturers – to apply these materials in practice and ensure they meet performance and sustainability targets.

Building and infrastructure owners – to support material selection and design choices that meet performance requirements and durability targets.

Demolition and recycling companies – to recover and reuse materials and components, keeping them in circulation instead of turning them into waste.

Regulators and policymakers – to provide scientific data and assessments that support the development of new construction standards and policies.

Questions we can help you with:

- How can we ensure the safety and reliability of materials and structures that must withstand decades of service?

- How can we protect and extend the lifetime of existing infrastructure and critical assets?

- How can we develop better-performing materials to gain a competitive edge in the market?

- How can we meet regulatory and sustainability targets with science-based methods?

- How can we turn industrial side streams or excess materials into valuable resources instead of waste?

- How can we estimate material and structural performance under unregulated exposure conditions (e.g. hydrogen or elevated temperatures)?

Related projects

- Seismic hazard prediction studies led by VTT since 2010, e.g.: Sensitivity study of seismic hazard prediction and Mitigation of induced seismic risk in urban environments

- Sustainable steel construction research led by VTT since 2017: PROGRESS - European Convention for Constructional Steelwork, ADVANCE - European Convention for Constructional Steelwork

- Long-term performance of wood research since 1980s: InCREased Service life of innovative TIMber Building systems. - VTT's Research Information Portal

- Väylä - Effect of excess air entrainment on behaviour of reinforced concrete structure 2018–2022. Effect of excess air entrainment on behaviour of reinforced concrete structure

- Strength studies of 100 bridges 2017–2018. 100 bridges: What did we learn – Fingerprint – VTT’s Research Information Portal

- Guidelines and material acceptance work for the Finnish Transport Infrastructure Agency, over 30 years of experience. SILKO-toiminta - Väylävirasto

- Ensuring safe and reliable long-term operations of NPP concrete structures research, led by VTT since 2020: ACES - Towards improved Assessment of Safety Performance for LTO of nuclear Civil Engineering Structures

- Immobilisation of low- and intermediate-level radioactive waste by cementation for improved safety and efficiency research, led by VTT since 2024: EURAD2 – European Partnership on Radioactive Waste Management

- Durability and sustainability of reinforced concrete structures in aggressive conditions research, led by VTT since 2025: COMPASS - Evaluating steel corrosion and concrete deterioration for improved and sustainable urban development in acid sulfate soils

How to work with us

We are happy to collaborate with you from the initial idea to implementation, or anywhere in between. Following an initial assessment, we can offer a range of options:

-

Customised partnership - Every research case is unique, and we’re happy to tailor our services to your needs. We’ll take you from an early concept to a tested and validated solution smoothly and efficiently.

-

Cooperative project - We frequently participate in research and development projects with multiple business partners and funding agencies. In cooperative projects, the risk is split between multiple organisations, and everyone benefits from the results.

-

Our networks and ecosystems at your disposal - You can benefit from our extensive research and industry networks. We are happy to put you in touch with the ideal sparring and development partners to support your goals.

Contact us here!

FAQ - Frequently Asked Questions about sustainable structural materials

What are sustainable structural materials?

Sustainable structural materials are materials designed for load-bearing and structural applications that reduce environmental impact across their lifecycle. This includes lowering carbon emissions, improving resource efficiency and enabling reuse, recycling or long service life without compromising performance or safety.

What types of materials does VTT work with in sustainable structural materials?

VTT works with a wide range of structural materials, including bio-based, fibre-reinforced, hybrid and low-carbon material solutions. The focus is on developing and validating materials that meet demanding mechanical requirements while supporting sustainability goals.

How does VTT support the development of sustainable structural materials?

VTT supports the full development lifecycle, from material design and modelling to testing, validation and scaling. This includes material characterisation, performance testing, durability assessment and sustainability evaluation to ensure solutions are ready for real-world use.

Which industries can benefit from sustainable structural materials?

Sustainable structural materials are relevant to multiple industries, including construction, infrastructure, manufacturing and mobility. Any sector that relies on strong, durable materials can benefit from solutions that reduce environmental impact while maintaining structural integrity.

How does sustainability get measured in structural material development?

Sustainability is assessed using data-driven methods such as lifecycle thinking, material efficiency analysis and performance based evaluation. This helps ensure that environmental benefits are achieved without shifting impacts elsewhere in the value chain.

This FAQ is written by AI and checked by a human.