Electric rotary kiln

VTT has developed a unique electric rotary kiln to support companies in testing and validating carbon efficient solutions that replace traditional and emission-heavy processes such as lime and cement production. We'll help you find ways to replace fossil-based solutions for calcination – while allowing CO2 capture in the process.

Key facts

Our experts and unique electric rotary kiln test & pilot infra support you in developing clean and efficient alternatives for traditional industrial processes that currently rely on fossil fuels.

Our knowhow of electric kilns can help industries with significant carbon footprints, such as the lime, cement, paper and mining industries, decarbonise their processes.

In addition to cleaner processes, industries can also capture the value of CO2 produced in the process by reusing or selling it.

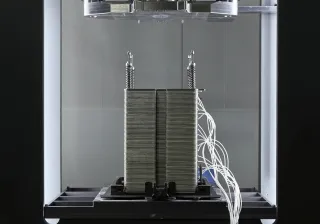

VTT’s electric rotary kiln technical specifications

Diameter: 0.54m

Length: 9m

Capacity: from 50 to 150 kilos per hour

Max temperature: 1050 °C

Drum rotation speed: 1-4 rpm

Calcination degree: high (up to 98% so far)

The cement industry responsible for 7% of global carbon dioxide emissions

The pressure to cut down emissions from industrial processes is growing. Regulations are tightening, and customers throughout the supply chain are increasingly demanding cleaner products and processes.

As we seek to rapidly decarbonise our societies, different industries face different challenges. The cement industry is responsible for around seven percent of the world's carbon dioxide emissions – making the footprint of the global aviation industry look small in comparison. And cement, the world's most widely used building material, is an exceptionally difficult material to replace.

Challenges and opportunities in carbon capture

An even bigger problem for the climate is the carbonate contained in limestone as it decomposes in the production process into carbon dioxide and quicklime.

Fortunately, when captured, carbon dioxide can be transformed into clean, sustainable fuel – and the market for it already exists. What is more, other lucrative use cases for captured carbon dioxide are being developed. These solutions are likely to significantly increase the utilisation of carbon dioxide and create new revenue opportunities for companies.

Electric rotary kilns enable sustainable manufacturing and CO2 capture

Electrically heated rotary kilns have the potential to revolutionise traditionally emissions-heavy industries such as cement, lime and pulp manufacturing. At VTT, we have proven that replacing combustion processes with electricity-based solutions is an effective way of decarbonising industries with process emissions.

Using electric rotary kilns, we can replace fossil-fuel based solutions for calcination and capture the carbon dioxide produced in the production process in high concentration.

This fossil-free technology can yield benefits for various manufacturing industries extending beyond calcination processes. These benefits include reduced environmental impact and decreased costs associated with fuels and emissions allowances. Furthermore, new business can be created with the CO2 captured in the process.

What we offer: a revolutionary electric rotary kiln process

VTT is at the forefront of innovation with our cutting-edge research on electric rotary kilns. Our state-of-the-art electric rotary kiln, developed through years of dedicated research as part of the Decarbonate project, demonstrates our expertise and capability. We offer a pilot kiln for testing various materials, showcasing our commitment to advancing clean and efficient industrial processes.

We are eager to leverage the technology to support ambitious companies who share our end goal of emission-free high temperature processes. That is why we are looking to partner with major industrial players and take the solution to the next level.

We are happy to be your innovation partner in:

- Validating the suitability of raw materials and the specifications of new machinery

- Experiments with selected raw materials using an electrically heated rotary kiln and fluidized bed

- CO2 capture technologies

- Purification and liquefaction processes of high concentration CO2

- Modelling electrically heated rotary kilns and fluidized beds based on test results

- Economic feasibility studies for industrial electrification concepts.

Some of the questions we can help you with

- How can we decarbonise our processes?

- What is the best technological solution for decarbonisation?

- How can we validate our material or recipe?

Why partner with VTT?

VTT has extensive experience and knowhow in carbon capture and utilisation or storage (CCU and CCS). We have developed numerous solutions and use cases for different industries, always with the same goal in mind: mitigating – or even reversing – climate change while creating valuable new products utilising CO2 as raw material.

With our technology, the pure carbon dioxide from limestone calcination can be captured, stored and used directly as a product or even further refined into fuels and chemicals.

We also have decades of deep systemic knowhow in industrial electrification methods and phenomenon management.

Video: Towards zero-emission factories

Excited response from the industry

Our industry partners’ initial reactions to VTT’s unique rotary kiln have been overwhelmingly positive. We look forward to working with more companies and industries to realise the potential of the electric rotary kiln in the decarbonisation of different industrial processes.

It has been exciting to see that the properties of best calcium oxides produced during the tests have been very close to product-grade burnt lime.

The raw meal of cement production was successfully treated in the trial runs to an intermediate product which is fully calcined but not yet reacted with silica, which is exactly what is wanted to achieve in a calciner.

DECARBONATE – revenue by electrification and CO2 utilisation

As part of the DECARBONATE project, VTT and its over 10 industry partners worked to enable industries to capture the CO2 with high-efficiency capture methods and utilise the CO2 as a product or further refine it into fuels and chemicals with the lowest carbon footprints.

For more information about the project, explore the final report.

How to work with us

-

Contact us!

Tell us what you want to do, and we will figure out how to do it. No project is too small or too ambitious – we would love to hear from you. After the initial assessment, we might be able to offer some of the following options.

-

Customised partnership

Every research case is unique, and we’re happy to tailor our services to your needs.

-

Cooperative project

We frequently participate in research and development projects with multiple business partners and funding agencies. In cooperative projects the risk is split between multiple organisations, and everyone benefits from the results.

-

Our networks at your disposal

We are happy to put you in touch with the ideal sparring and development partner.

Meet our experts

Eemeli Tsupari is specialised in climate change mitigation and energy system analysis. He worked as a project manager in Decarbonate project, where VTT's electric kiln was commissioned and the first experiments conducted.

Oona Louhola is specialised in industrial decarbonisation solutions. Her recent research activities are focused on electrification of lime and cement manufacturing.

Contact us here!

FAQ - Frequently Asked Questions about electric rotary kiln

What is VTT's electric rotary kiln and its purpose?

VTT has developed a unique electric rotary kiln to support companies in testing and validating carbon-efficient solutions that replace traditional fossil-fuel-based processes, such as those used in lime and cement production.

How does the electric rotary kiln contribute to CO₂ capture?

The electric rotary kiln enables the capture of carbon dioxide produced during the calcination process in high concentration, facilitating carbon capture and utilization efforts.

Which industries can benefit from this technology?

Industries involved in cement and lime production, as well as other manufacturing sectors seeking to reduce environmental impact and fuel costs, can benefit from VTT's electric rotary kiln technology.

What are the environmental advantages of using the electric rotary kiln?

By replacing fossil-fuel-based solutions with electric alternatives, the kiln reduces greenhouse gas emissions and supports the creation of new business opportunities through captured CO₂.

This FAQ is written by AI and checked by a human.