With access to VTT’s state-of-the-art microfabrication tools, expert maintenance and an open operating model unique in Europe, AR waveguide developer Dispelix can scale its R&D efficiently while contributing to the growth of Finland’s microelectronics and photonics cluster.

Key facts

Developing high-performance optical waveguides requires advanced cleanroom infrastructure that would be prohibitively expensive for smaller companies to build and maintain independently.

VTT’s shared-use cleanroom at Micronova provides Dispelix with flexible access to fabrication tools, a professional maintenance team and a stable environment for both early R&D and scaling activities.

Dispelix can accelerate development, iterate quickly, utilise hybrid operating models and prepare for pilot-scale production – all without massive capital investments.

Founded in 2015 as a VTT spinoff, Dispelix develops and delivers transparent waveguides for enterprise and consumer augmented reality (AR) devices. The company’s advanced waveguides function as see-through displays, fusing the real and virtual worlds within the user's field of vision. Dispelix positions itself as a trusted and visionary partner for the industry leaders in AR, enabling them to redefine the form, function and feel of AR devices.

Growing demand for waveguides and advanced microfabrication

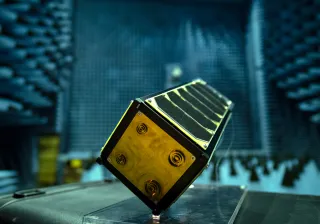

The global semiconductor and AR industries are expanding rapidly, driven by demand for immersive interfaces, ultra-compact imaging systems and next-generation wearables. Transparent waveguide displays – thin optical components that use total internal reflection to guide light within a lens-shaped substrate – are foundational to this shift. Producing them requires nanostructures far smaller than the wavelength of visible light. These highly precise geometries demand industrial-grade cleanrooms, stable process environments and advanced micro- and nanofabrication equipment.

Finland’s microfabrication capabilities, anchored in the Micronova cleanroom, play a key role in Europe’s strategic push to build sovereign microelectronics and photonics capacity. By opening the cleanroom to external companies, VTT provides a platform where spinoffs, startups, research groups and industrial partners can all advance their technologies on shared high-end infrastructure.

This service model gives us scalability without hiring full-time operators.

A unique shared-use model with deep expertise

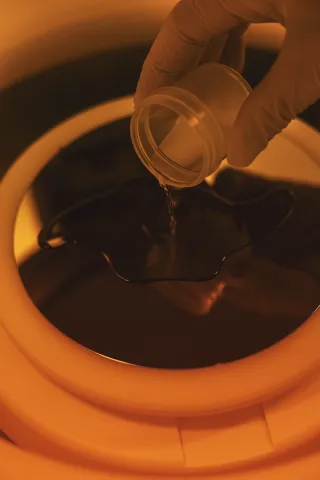

The optical gratings inside Dispelix’s waveguides typically measure only 200–300 nanometres. This calls for extremely clean, particle-free processing conditions and tools capable of nanoscale patterning.

“Waveguide development demands an environment where every source of interference is removed. A single dust particle can ruin the final optical performance. To make structures this small, we need advanced cleanrooms and the same fabrication technologies used in the semiconductor industry,” says Joonas Heikkinen, Cleanroom Operations Director at Dispelix.

VTT’s shared-use cleanroom allows external companies to access tools and work directly inside the facility. This model, rare in Europe, has been instrumental for Dispelix’ growth.

“As our primary substrate is glass, not silicon, it’s essential that our own specialists handle the work, because our way of working differs fundamentally from standard wafer fabrication. The flexible hybrid model also allows us to train VTT operators to run specific processes when needed. This gives us scalability without hiring full-time operators,” Heikkinen points out.

He adds that building up even a fraction of the infrastructure independently would require tens of millions of euros and lengthy process development.

Boosting industrial relevance with infrastructure upgrades

The capabilities provided by VTT to Dispelix have included:

A stable, professionally maintained cleanroom environment

An extensive range of nanoscale microfabrication tools

A flexible operating model, combining hands-on engineering and operator services.

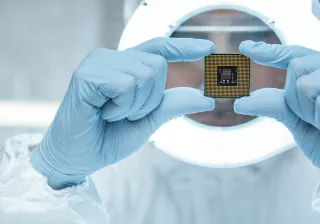

In 2025, VTT completed the conversion of its cleanroom from 150 mm to 200 mm wafer processing capability.

“Our cleanroom is now compatible with the wafer sizes used in many other European R&D cleanrooms. Thus, it offers an even wider range of opportunities for its users than before,” says Piia Konstari, VTT’s Director of Microfabrication Services. She adds that the upgrade is part of a broader European strategy:

“Our goal is to build a leading European microelectronics R&D and piloting cleanroom, supporting research, development, innovation, piloting and industrialisation. This investment strengthens Finland’s role in the specialised microelectronics ecosystem.”

For Dispelix, the upgrade means more stable processes, improved tool performance and closer alignment with semiconductor industry partners.

When companies, researchers and new capabilities concentrate in one place, the whole ecosystem becomes more attractive.

Looking ahead: Kvanttinova initiative strengthens the ecosystem

The new Kvanttinova hub and Kvanttinova ecosystem is a joint initiative by VTT, Aalto University, the City of Espoo and industry partners. It will expand Finland’s capabilities across microelectronics, photonics and quantum technologies.

Heikkinen sees major promise in this development: “Kvanttinova hub could really accelerate the positive spiral we already see in Micronova. When companies, researchers and new capabilities concentrate in one place, the whole ecosystem becomes more attractive – for talent, for investment and for collaboration.”

Heikkinen highlights the importance to Dispelix of Aalto University’s presence within the shared hub – particularly for early experimentation and small-scale testing.

“Aalto University plays a vital role for us. Their focus on research complements VTT’s more industrialisation-oriented environment. It means we can try out early R&D concepts and small sample batches before moving into more advanced development by using the toolbase of both organisations.”

He concludes that this proximity of complementary capabilities – academic research, industrial-grade R&D and piloting – provides Dispelix with a highly versatile development path that would be extremely difficult to replicate elsewhere.