Printed and flexible electronics

VTT’s research infrastructure supports your printed and flexible electronics projects from the proof-of-concept stage to manufacturing process development and technology transfer.

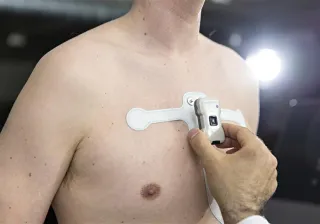

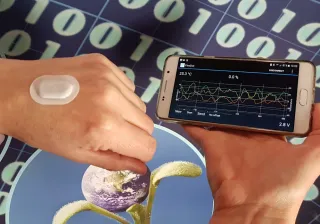

With VTT you can research and develop printed and flexible electronic solutions such as flexible, lightweight organic solar cells, illuminating surfaces, smart patches that enable sensor integration directly on skin and communicating labels for packaging.

Our unique combination of over 100 multi-technological experts and the award-winning pilot factory PrintoCent serve the R&D needs of dozens of companies every year. The PrintoCent Pilot Factory offers unique, world-class roll-to-roll pilot processing facilities and experienced staff for high throughput manufacturing process development.

PrintoCent also brings together companies from different industries: the PrintoCent Industry Cluster has 40 member companies ranging from automotive to ICT and diagnostic business sectors – one of these companies may well be your future partner in manufacturing, or offer suitable technology for your project.

Our key infrastructure:

- Roll to roll printing on continuous 300 mm wide web with rotary-screen, gravure-, flex-printing, and slot die and bar-coating methods.

- Post-processing and converting using laser-, die- and kiss-cutting as well as lamination processes (Delta Modtech Converting line)

- Two integrated robot assembly arms (Yasagava), placement and welding

- Pick-and-place assembly for chip and flexible component bonding

- Roll-fed assembly lines for high-accuracy flip-chip bonding for ACA (Anisotropic Conductive Adhesive) bonding and high throughput assembly line for ICA (Isotropic Conductive Adhesive) bonding (customised roll-fed pick-and-place line)

- Functional foil in-mold-integration (IMI) process with roll feeding for plastic integrated and structural electronics

- Functional tester line

- Processing line for PDMS imprinting and casting

- Reverse offset printing machine for sub-micron accuracy printed electronics

- Diagnostic lab for biosensor integration

- State of the art TOF-SIMS (located at CNS)

The pilot factory and VTT’s expertise can be utilised to develop proof of concepts for various applications. Furthermore, process upscaling can be proved using our versatile capabilities.