Computational material design – VTT ProperTune®

VTT ProperTune® is our Integrated Computational Materials Engineering (ICME) concept that uses multiscale modelling for optimal computational material design. With VTT ProperTune® you can virtually create microstructurally accurate materials and load in realistic conditions – whatever the material, whatever the challenge. It can replace expensive, time-consuming testing and shorten the time-to-market for new products by an average of 50%.

Key facts

VTT ProperTune® can shorten the time-to-market for your new products by 50 %

Systematic optimisation of e.g. wear, fatigue, fracture resistance or barrier properties

Deeper understanding of material degradation mechanisms

Optimise material properties with VTT ProperTune®

VTT ProperTune® can parse massive amounts of data to virtually model and analyse material behaviour on component, microstructural and atomic scales. It is used to optimise a wide variety of material properties, such as lifetime endurance, wear and corrosion resistance and fracture and fatigue durability.

VTT ProperTune® has been developed together with our industrial partners and applied to their critical processes and components in, for example, biomaterials, mechanical machines and devices.

How to use VTT ProperTune®

With VTT ProperTune® you can digitally mimic both industrial and biomaterials, and accurately predict how they behave under real service conditions. The material characterisation and verification processes ensure that the results are reliable.

The applications of VTT ProperTune® are extremely broad. Accurate modelling can be applied to almost any material and surface coating, for example:

- Biomaterials

- Metals

- Ceramics

- Elastomers

- Plastics

- Coatings

- Composite structures

- Sandwich structures

VTT ProperTune® example cases

Caterpillar

Optimization of protective coatings.

Outcome: coating solution performance improvement 40%.

Konecranes

Lifetime of industrial crane sheave-wire rope contact.

The critical sheave to wire rope sliding-rolling contact was analysed with regard to fatigue and wear life for cast iron vs steel material pairs.

ArcelorMittal

Discovery and design of new steel grades.

Outcome: New steel performance improved ~200-250%.

Metso Minerals

The impact wear resistance of steels, composites and elastomers were analysed and wear life optimised for severe mining conditions by multiscale material modelling and simulation.

Wärtsilä

Discovery and design of new steel grades.

Outcome: New steel performance improved ~200-250%.

Kone Oy

High resolution mechanical and multiscale material models were developed for cast iron and coated components to predict wear, estimate lifetime and select optimal wear resistant materials.

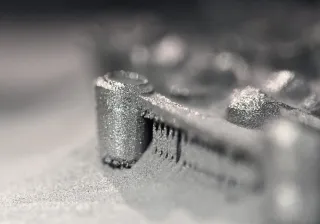

Example of ICME solution for metal additive manufacturing

VTT ProperTune® is the key to durable products. Well begun is half done – up to 80% of the cost and benefits of materials is based on decisions made in the design phase.

From ICME towards MAPs

Materials innovation is entering a new era. This white paper introduces how moving from Integrated Computational Materials Engineering (ICME) towards Materials Acceleration Platforms (MAPs) is fast-tracking the discovery of high-performance, sustainable materials.

Video: VTT ProperTune helps to design durable materials

How to apply material microstructure to full-scale systems

Integrated Computational Materials Engineering (ICME) provides a systematic, requirement-based design approach and digital framework for material discovery, design and optimisation using AI/ML technologies.

VTT ProperTune® enables the rapid development and deployment of ICME solutions. This is achieved by using multiscale modelling and computational material design approaches such as the Process-Structure-Properties-Performance (PSPP) principle.

Performance-driven computational material design process:

Find our publications related to computational material design

How to work with us

When it comes to applications VTT ProperTune®, there are many ways to utilise our expertise.

-

Contact us!

Tell us what you want to do, and we will figure out how to do it. No project is too small or too ambitious – we would love to hear from you. After the initial assessment, we might be able to offer some of the options listed below. -

Customised partnership

Every case is unique, and we’re happy to tailor our services to your needs. -

Cooperative project

We frequently participate in research and development projects with multiple business partners and funding agencies. In cooperative projects the risk is split between multiple organisations and everyone benefits from the results. -

Our networks at your disposal

We are happy to put you in touch with the ideal sparring and development partner.