The long-term collaboration between VTT and Elcogen has evolved from a product development project into a strategic partnership. By combining its cutting-edge solid oxide technology with VTT’s world-class validation infrastructure, the partners have accelerated the commercialisation of high-performance solutions for the green transition.

Key facts

In the company's startup phase, Elcogen needed independent validation and specialised infrastructure to complement its in-house engineering capabilities and support the commercialisation of its stacks.

VTT supported the early development and validation of Elcogen’s solid oxide stacks, hosted pilot-scale manufacturing activities, and provided flexible characterisation and testing services.

The partnership has accelerated Elcogen’s R&D cycles, reduced scale-up risk, and provided the credible data needed to secure customers and EU funding, reinforcing Elcogen’s position as a trusted solid oxide technology supplier on the global stage.

Founded in 2001, Elcogen is a manufacturer of clean energy technology that delivers affordable green hydrogen and emission-free electricity. The company is focused on driving net zero ambitions forward with a core, reversible technology that converts fuel sources into emission-free energy and emission-free energy into green hydrogen.

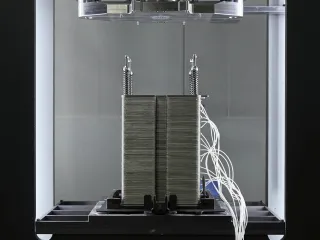

Elcogen’s core solid oxide fuel cell (SOFC) and solid oxide electrolysis cell (SOEC) technology is flexible and can be applied to a broad range of residential, industrial and commercial applications, enabling multiple types of systems to produce and use green energy.

The dual power of solid oxide technology

Fuel cell systems have the potential to reshape how the world is powered, enabling efficient, clean and reliable off-grid energy generation. They can help us sharply reduce our use of fossil fuels, transferring to cleaner sources and eventually to renewably generated hydrogen.

Today, Elcogen’s components – cells, stacks and modules – are integrated into third-party systems for a wide range of applications including distributed energy, off-grid and stationary power, industrial backup, green hydrogen production and Power-to-X solutions.

VTT’s ability to test across different technology readiness levels (TRL) allowed us to validate our products under rigorous conditions.

Bridging the gap from component to system

Fifteen years ago, the energy landscape was different. Elcogen sought to combine its cells into a stack to make integration into customer systems easier and faster, thus expediting the energy transition. The pioneering startup wanted to industrialise solid oxide technology at a time when few organisations globally were addressing full stack-scale manufacturing.

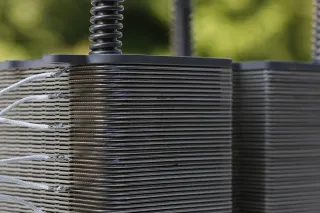

“When Elcogen signed up to be a manufacturer of SOFC cells, they were keen to build the solid oxide stacks themselves. But at that point, they lacked the specific experience and know-how regarding stacks,” recalls Jari Kiviaho, Research Professor at VTT.

Furthermore, for a startup, proving long-term reliability without a massive internal laboratory is a critical bottleneck.

“As a growing company, we had limited access to the infrastructure needed for prototype characterisation and validation. Obviously, we can’t simply deploy products into the field to generate data; we need a laboratory-scale environment to learn how they behave before going to market,” says Antonio Alfano, R&D Manager at Elcogen.

Accelerating R&D through partnership

The turning point came when Elcogen tapped into VTT’s deep reservoir of expertise. What started as a single development project soon blossomed.

“In the early stages, Elcogen’s stack development and manufacturing were actually carried out at VTT’s premises,” Kiviaho notes. "This support made it significantly easier for the company to launch its operations.”

VTT’s role expanded to providing what Elcogen’s Chief Technology Officer Jan Gustav Grolig describes as a “neutral stamp of approval”.

“VTT’s ability to test across different technology readiness levels (TRL) – from explorative small-scale research to quasi-demonstration units – allowed us to validate our products under rigorous conditions,” Grolig notes.

Beyond just machinery, the intellectual capital was crucial. Alfano emphasises the value of VTT’s critical eye: “We benefit immensely from honest feedback. VTT doesn't just present sterile outcomes; they provide a critical assessment of the test campaigns, which is always valuable.”

Our collaboration with VTT has been instrumental in supporting Elcogen’s growth from a technology developer to a global supplier.

Building trust and strategic growth

As part of the ongoing partnership, VTT has provided Elcogen with:

World-leading characterisation infrastructure

Flexible R&D platforms and deep technical know-how

Strategic project facilitation.

Today, the collaboration is a cornerstone of Elcogen’s commercial strategy. In an industry where reliability is paramount, independent validation is the currency of trust.

“Having data to back up our quality claims gives customers proof that the technology they are investing in actually works,” explains Alfano. “This builds the trust necessary to secure customers and strategic investors.”

For VTT, the feeling is mutual: “The collaboration grew from small streams to where Elcogen is now one of our most important customers in this area of research,” says Olli Himanen, Research Team Leader at VTT. “We have characterised their products, helped with development and facilitated their involvement in EU projects. We have benefited equally from the collaboration – Elcogen has, for example, invited VTT to participate in joint projects that we wouldn’t have otherwise been able to access so easily.”

Ultimately, the partnership has matured into a strategic alliance that accelerates the entire industry.

“Our collaboration with VTT has been instrumental in supporting Elcogen’s growth from a technology developer to a global supplier. Having a trusted Nordic partner with first-rate R&D infrastructure and deep validation capabilities has enabled us to scale with confidence and build trust in our technology worldwide,” concludes Elcogen CEO and founder Enn Õunpuu.