Future of Biofuels 2025

On this page you’ll find concrete examples and practical case studies showing how VTT helps biofuel companies reduce risk, accelerate development and scale emerging technologies from lab through pilot to market.

Global and EU-level climate targets are pushing for low-emission alternatives to fossil fuels, making biofuels a strategic solution for decarbonising transport and industry. Legislation in Europe incentivizes biofuel adoption. The biofuel industry needs to balance between the need for greater sustainability and the demands of economic competitiveness and energy security.

VTT can help biofuel companies to reduce investment risks and time-to market by developing and piloting novel upgrading path to renewable fuels. With the help of our world-class infra and capabilities in biomass upgrading we can support companies in developing and piloting sustainable chemical processes. We are flexible in benchmarking new catalysts and feedstocks.

Electrochemical processes: a breakthrough for sustainable chemical production

Electrified chemical methods can transform CO₂ and bio-based feedstocks into valuable products. This article explains the progress made, the challenges ahead and the potential for low-carbon production.

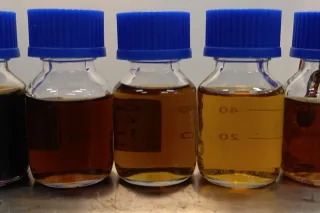

Fast pyrolysis of biomass: breaking free from crude oil

Fast pyrolysis can turn biomass and residues into bio-oils that can be upgraded into high-value chemicals. Learn how this technology supports the shift away from crude oil, and what challenges remain.

Case Neste: from fossils to renewables

Discover how VTT and Neste joined forces to push renewable raw material research forward and bring circular chemistry innovations to market faster.

CaSH research project: a novel path for bio-oils

The CaSH project developed a new route for transforming bio-oils into higher-value products. It offers a concrete example of how biomass can become a driver of sustainable growth.

Chemical process technology infrastructure

VTT’s chemical process technology infrastructure supports companies and research partners in developing and piloting sustainable chemical processes from lab to pilot scale. With extensive expertise, on-site analytics and advanced pilot plants, we enable faster, safer and more cost-efficient scale-up of new materials and processes — from renewable and recycled sources to future separation and recovery technologies.

4 feedstocks and technologies to decarbonise the oil and gas industry

Explore four promising non-fossil feedstocks — from waste plastics to biomass — and the technologies that enable their use. This white paper outlines practical routes for decarbonising the oil and gas sector.

Contact our experts