Scales and various metering dispensers are important in the manufacture of medicines, fuels and explosives. From the point of view of product safety and efficacy, it is essential that these measuring devices are properly calibrated, regardless of whether we are experiencing an upswing or exceptional circumstances.

Metrologically traceable measurements are essential for the operational capability of aircrafts – whether they are Finnair's Airbus passenger planes or the Air Force's Hornet fighters.

The situation in Ukraine reminds us that metrology services are important even in wartime

The resilience of the metrology services provided by society is currently being tested in Ukraine, where Russia bombed the Ukrainian metrology institute in the early stages of the war. Despite the enormous efforts required by the war, Ukraine is investing in metrology and, with the support of European metrology institutes, is working to ensure its country's calibration and testing services, as they are vital for security of supply and defence capability.

The importance of metrology services was also recognised in wartime Finland. A concrete example of this is the transfer of the most important reference measuring devices – the kilogram prototype and the metre prototype– from Helsinki to a safer location in Vaasa.

When a crisis hits, there is lack of time for development and help may be far away

The development of metrology capabilities and services would take years even in peacetime. Fortunately, Ukraine already had a well-developed metrology infrastructure before the war, which it can now use and develop in accordance with current needs, despite the damage. During another kind of recent crisis, the coronavirus pandemic, we experienced how late we are if we start developing measurement and testing services only when the situation is acute. It is especially difficult if there are no expertise and infrastructure to serve as a basis for new development.

During the coronavirus pandemic, we also learned that by relying solely on foreign service providers, we may not get the services we need at all, or access to them is too slow. Cargo traffic across the Baltic Sea also plays a key role in the use of foreign calibration services. Marjut Linnajärvi, Business Director at Nurminen Logistics, points out in an article in Tekniikka ja Talous on 29 August 2025 that it will take a long time after a blockage of sea traffic before Finnish cargo traffic can be transported through the north to Sweden and further.

The reliability of electricity distribution requires the development of metrology

The electricity network is the lifeline of today. A long-term complete power outage paralyzes homes, shops and factories. A dramatic reminder of this was the widespread blackout in the Iberian Peninsula at the end of last April.

The complexity of electricity networks is increasing with the addition of different energy sources and energy storages, which increases the need to develop test methods for network components and calibration methods for the equipment used for testing. The requirements for time synchronization are also increasing. VTT MIKES is carrying out this development work together with other leading research institutes in the field. Case Study reports published by EURAMET e.V. show that the achieved results and standardised methods contribute to the operational reliability of electricity networks.

International research builds future security of supply

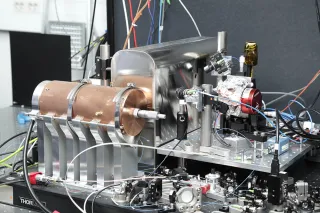

GPS jamming incidents in Finland's eastern border areas have shown how important it is to develop a satellite-independent time synchronization system and thus ensure the availability of the national UTC(MIKE) time provided by VTT MIKES even where the most accurate synchronization is needed. The demands of the quantum computing age of the future are even greater, which is why we at VTT MIKES are investing in the development of optical clocks and fibre links.

The development of production technologies in both the civil and defence industries requires the development of new calibration methods and services. For example, electronic components and various optical components utilise increasingly smaller structures, the production of which requires more accurate and efficient quality assurance methods. New types of calibration solutions are needed in increasingly complex measurement systems that utilise artificial intelligence.

We cannot solve these future challenges in Finland alone. We need international metrology research so that we can build metrology services that meet the needs of future security of supply.