Optical spectroscopy

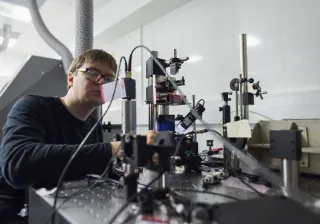

Optical spectroscopy technologies have nearly endless application potential for industries ranging from defense to health and forestry to recycling. At VTT, we have a team of more than 30 world-class researchers working side-by-side with our partners and customers to develop trailblazing, tailored optical spectroscopy applications for demanding environments.

Key facts

VTT specialises in highly customised optical spectroscopy solutions for difficult environments. Our key expertise is in optical design, Raman spectroscopy, as well as near-infrared (NIR) and mid-infrared (MIR) spectroscopies.

We have close to 40 years of experience in optical spectroscopy projects, and our research expertise combines optics, mechanics, instrumentation, data analytics, algorithms, software and more.

Our optical spectroscopy -based technologies have a wide range of application areas including paper & plastics industry, emissions and environmental monitoring, health tech, mining & steel, agriculture & food, robotics, circular economy, and biotechnology

At VTT, we have 40 years background on optical sensor development and instrumentation for on-line measurements. We specialise in applications and solutions for scenarios, where bridging the gap between optical measurement technologies and industrial applications requires a high-level expertise. In particular, our unique combination of skills and experience allows us to develop sensor applications for harsh industrial environments where heat, moisture, dust, and space limitations add additional demands to the solutions’ usability.

Our application areas include

- Metal, steel, paper and pulp

- Mining, mineral processing

- Waste sorting

- Pharmaceutical manufacturing, process monitoring

- Consumer applications

- Defense, intelligent traffic, and law enforcement

- Forestry, agriculture and food

- Recycling

- Breath analysis

- Emissions monitoring

- Nuclear facilities

In addition to high level of technological and research expertise, our work is supported by VTT’s extensive international networks in academia and across industries as well as our strong research infrastructure supporting design, characterization, prototyping and experimental work. VTT also operates as the National Metrology Institute of Finland (VTT MIKES), offering ways to demonstrate reliability and traceability of measurements, calibration services as well as consultation and training.

We specialise in applications and solutions for scenarios, where bridging the gap between optical measurement technologies and industrial applications requires a high-level expertise.

Optical design

At VTT, we offer our customers a comprehensive “one-stop-shop” for customised instrument and measurement solutions for both imaging and non-imaging optics. We offer a skillset that combines optics design, simulation, design for manufacturing, prototyping and characterization which makes us the ideal partner for a range of trailblazing optics design projects.

We are able to support you in all aspects of your optical design project including:

- Optics and illumination

- Mechanical design

- Electronics

- Industrial Design

- Software

- Prototypes

- Data analytics, algorithm development, & calibrations

Examples of our customized spectroscopic devices and measurement solutions range from field-capable handheld sensors to customised probes for industrial processes.

Raman spectroscopy

At VTT, we developed advanced raman spectroscopy solutions for material analysis. Our services include:

Specialised probe design and manufacturing:

- Optical design using Zemax

- On-line, in-line probes

- Autofocus, remote functionalities

Application know-how and material analysis by:

- Multivariate data analysis

- Peak height algorithms and statistical analysis

- Automated analysis for on-line application

Infrared spectroscopy

VTT develops near-infrared spectroscopy (NIR) and mid-infrared spectroscopy MIR spectroscopy for several process and material analytics applications industries ranging from pulp and paper to food and mining. Our instrumentation can be fully customized to fulfil the requirements of each unique application from optical solution development to calibration.

At VTT, we have developed instrumentation from handheld devices to analysers for high velocity 10 m wide webs. Online measurement enables performance and cost-optimised process control, quality control and raw material usage.

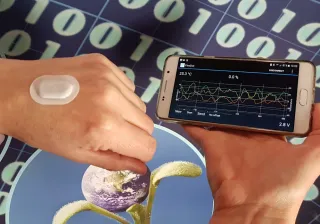

VTT also has expertise in applying some of the most sensitive laser spectroscopy techniques in the mid-infrared wavelength region for molecular trace gas sensing and isotope analysis. Among other techniques, VTT has applied cavity enhanced techniques and photoacoustic spectroscopy in a variety of applications, such as emission monitoring in nuclear facilities or breath analysis.

VTT uses active hyperspectral sensing for remote reflectance measurement up to 2500 nm under any illumination conditions, enabling material identification over distances up to several hundred meters. The use cases for this technique include mineral mapping, border control and material sorting.

Our instrumentation can be fully customized to fulfil the requirements of each unique application.

Successful spin-offs show the commercial potential of optical spectroscopy innovations

While we work with our partners and customers to develop tailored optical spectroscopy solutions for new and existing industrial processes, our innovations have also produced successful startups. Over the last 30 years, our research has been a launch pad for new businesses. Startups based on spectroscopy and sensor technologies developed at VTT have exceeded EUR 30 million in value and employed 250 people.

Companies including Specim Ltd, Spectral Engines, Dispelix, Focalspec (now part of LM3D) and GrainSense have entered markets with innovative solutions for applications ranging from anti-counterfeit sensors for pharmaceuticals, and grain quality measurements to AR smart glasses displays.

Project: GoldenEye

In 2020, the European Commission granted EUR 8.4 million to a three-year H2020 project that develops an artificial intelligence platform for the monitoring and analysis of mine sites across Europe. The GoldenEye project will develop solutions that improve safety, environmental impact and profitability of mines by creating a platform that combines earth observation technologies with on-site sensing.

Other projects

Our other ongoing joint projects and ecosystems include

- diagnostics sensor SensApp

- border surveillance technology Foldout Solution

- CHANCE: Characterization of conditioned radioactive waste

Case: VTT partnered with Fortum to improve and test a new method for power plant monitoring

VTT and Fortum worked together to develop a new method for the monitoring of stack emissions for the presence of carbon-14 in the context of nuclear power plants. C-14 is a radioisotope of carbon whose emissions into the atmosphere must be controlled. The new approach uses laser spectroscopy to reduce the time, labour and ultimate cost of these measurements.

How to work with us

-

Get in touch today!

If you’re looking for highly customised optical spectroscopy solutions for demanding environments, we want to hear from you. We are eager to hear about the needs of your company and the challenges you seek to tackle. -

Explore beyond the obvious solutions

We work on optical spectroscopy solutions with customers from different industries and take pride in understanding each business as we explore tailored technological solutions that go beyond the obvious. -

Together from idea to commercial success

We have the experts and the equipment to be your partner all the way from an early concept to tailored piloting and commercialisation. Our offering includes:- application feasibility analysis services

- laboratory and onsite assessment and trials with customized test set-ups / instrumentation

- instrument development, to proof-of-concept level

- support for commercialization of optical technologies, technology transfer and IPR licensing