Creating black plastic separation methods is an important goal in promoting the circular economy of materials. The plastic should maintain high quality during the cycle as long as possible. Research Scientist Francisco Senna Vieira is involved in finding new separating solutions with the help of better sensors and hyperspectral imaging.

Francisco Senna Vieira did his PhD in Brazil on sensing and analytical chemistry. He worked for a year at NIST National Institute of Standards and Technology in the US and ended at VTT after a postdoc period at the University of Helsinki and Umeå University.

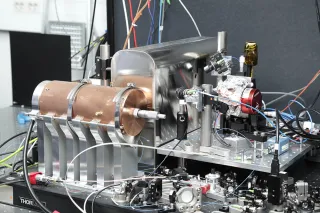

VTT’s Optical Spectroscopy team develops different types of sense optical sensors for various applications. Part of the work is to develop sensors for gas sensing and isotope detection. One example is the development of sensors to detect radioactive carbon 14 for distinguishing biofuel from fossil fuel.

“Since I started at VTT four years ago, I have been working on two main topics. We developed hyperspectral sensors to optimize the efficiency of mining. In a mine you need to take a lot of rocks to a laboratory for composition analysis and this takes time and resources. We have ideas how sensors could be used to do the sensing on location”, he says.

“Lately, I have been focusing on circular economy and sensors to identify different types of materials for recycling. The problem is that mixed plastics cannot be recycled well. These materials need to be sorted before being finally melted and manufactured into new material”.

Two of the main plastic types found in WEEE waste (Waste from electrical and electronic equipment) are ABS (acrylonitrile butadiene styrene) plastic which s used for 3D-printing and high impact polystyrene (HIPS). They are typically black and used in many smartphones, laptops and computer screens.

“If you want to use ABS for a smartphone it needs to be of very high quality – with very specific parameters for the plastic. If you have separated, let’s say 80% of ABS and 20% of some other plastic, you can’t use it in your application. If your heap of waste plastic is mostly black, you have a problem.”

Maintaining the value of material during circulation

“If you cannot separate the material the only thing you can do is to reduce the value of your circulated product. You end up reducing the value of the material if you have to use it for toilet brushes instead of smartphones. The target should be keeping the quality of the recycled plastic as good as the original plastic was for as long as possible”, he says.

“Current sensors on industrial recycling facilities’ conveyor belts work to detect if the mixed waste contains, e.g., polyethylene or other types of plastic. A part of what we are developing at VTT is to help industry to also separate the black pieces automatically.“

“The first jointly funded project I was involved was the EU-funded NonTox that aimed at detecting a specific type of additive that is common in plastics used for electrics and electronics. In electronic equipment, laptops and smartphones, for example, you need fire retardants as a safety measure. Some of them contain brominated flame retardants, and you cannot recycle such hazardous material. There are also other products with other types of chemicals, volatiles that can be toxic and harmful to people and the environment.”

“In the NonTox project, we created AI algorithms that use the sensor data to quantify the amount of flame retardants. Once you can identify what you have, you can separate the waste and get material for normal recycling and material that needs treatment to remove flame retardants.

Black plastic challenge on conveyor belts

A typical sensor used in conveyor belts works with near-infrared lights that are not able to detect the colour black. The colour comes from a pigment called carbon black. You can add this pigment to any type of plastic. That’s why you can’t tell the difference between plastics made black with this pigment: they are the same to the sensors.

The industry has been moving forward in using sensors that operate in different wavelength ranges. The idea is to use the light information to assist in the separation.

The project Broadband active hyperspectral sensing for black plastic identification Broadband active hyperspectral sensing for black plastic identification has got a proof-of-concept funding from the Academy of Finland of 300 000 euros for two years, and it started last year.

“Our plan is to collaborate with a few recyclers from the industry. Our aim is to tailor sensors according to the needs of the members of the industry. The project is still in the early stages. First, we will be working in the laboratory developing the sensors and testing them. Next year, we will proceed to the first pilots.”

The end goal is that the technology would lead to a higher technology readiness level (TRL) prototype, and that it could be tested in industrial facilities.

“The novelty in our new project is a supercontinuum light source. It is a type of laser that covers a very wide infrared range. It’s also very bright and it gives a strong signal. We hope that with this type of light source we can get a better signal from black plastic. We are currently developing a fast-scanning spectrometer to utilize it in a sensor on a conveyor belt”, says Francisco.

Separating degraded plastics

It's also important that you make sure that the properties of the plastic have not been degraded. The material may have been exposed to ultraviolet light, heat or moisture which degrade the quality of plastic. This irreversible chemical aging means that you have to use it in lower value applications.

“I am working in a European project called Primus, where we use sensors for measuring the degradation degree of plastics.”

Hyperspectral imaging technology

The possibilities of hyperspectral imaging are well applicable to be used in plastic recycling.

“While the most common sensors are single point sensors, hyperspectral imaging offers an image with a line of pixels. When detecting heterogenous waste on a wide conveyor belt, it is much better to have an image instead of a single point. While traditional camera uses three wavelengths a hyperspectral image can offer 100 different colours, depending on the device. It can give information of the chemical composition, and you are also able to detect different pieces of plastic and different shapes. Combined with spatial information and AI models you have more information to separate different materials, such as plastic”, says Francisco.