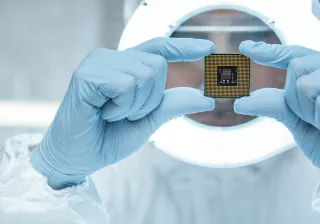

Finland has become an internationally significant player in the field of specialised microelectronics and semiconductors. The shared-use cleanroom in Otaniemi is at the core of this development. It offers companies and research communities a unique environment for innovating, experimenting and commercialising new technologies. The cleanroom now supports 200 mm wafer size, thus offering increased opportunities for its users.

Read the summary

- VTT’s cleanroom facilities act as a breeding ground for sustainable innovation, serving numerous companies and creating a thriving business ecosystem with long-standing traditions.

- Shared infrastructure allows small and large enterprises to innovate and experiment efficiently, with recent upgrades to support larger wafer sizes further expanding opportunities for users.

- VTT provides comprehensive support and R&D services in their cleanroom environment, helping businesses to grow from using shared infrastructure to eventually investing in their own manufacturing capacity.

This summary is written by AI and checked by a human.

The Otaniemi cleanroom environment is unique in many ways. By providing an infrastructure for chip fabrication and development, it has enabled the establishment and operation of several companies. VTT, Aalto University and companies are constantly developing new technologies and intellectual property rights in Otaniemi. The cleanroom environment is reliably maintained and constantly developed to support and serve the Finnish society and its growth over the long term.

The chip industry has an important role to play in Finland’s competitiveness

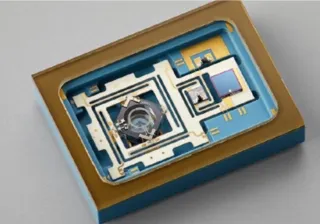

Developing, designing, manufacturing and utilising new technologies and know-how in the field of critical technologies are important goals for us. Finland has internationally recognised strong expertise in specialised microelectronics, such as RF technology, MEMS, integrated photonics, material and process development, integration technologies and superconducting quantum technology.

The semiconductor sector employs approximately 7,000 people in Finland. According to the Chips from the North strategy published by the Technology Industries of Finland, the sector aims to triple the number of jobs by 2035. The value added brought by the semiconductor industry to Finland is many times higher than that brought by the low-end industries. When technologies are both developed and commercialised in Finland, their intellectual property rights remain here, thus helping to ensure Finland’s long-term competitiveness.

There are various key microelectronics RDI hubs in Finland, the largest ones being the Helsinki Metropolitan Area and the Tampere and Oulu regions. The regions of Turku and Joensuu also have activities based on their own areas of special expertise.

Otaniemi cleanroom environment as an enabler of sustainable innovation

Otaniemi’s open semiconductor infrastructure and the business ecosystem formed around it have long traditions. VTT has offered companies the opportunity to utilise their cleanroom facilities for decades. This has enabled the growth of a tight business ecosystem, which is utilised by VTT and Aalto University spin-off companies, SMEs in the region and large international corporations with R&D activities in Finland.

The ecosystem has been evolving around the Otaniemi semiconductor infrastructure since the 1990s, when Micronova was built. Micronova has enabled the creation of numerous innovations and new business activities. A total of about 30 companies operate or have operated as part of the Otaniemi ecosystem. Many of them are currently on a good growth trajectory.

Enterprises benefit from shared-use infrastructure

Shared-use semiconductor infrastructure is vital for many businesses because spin-offs and SMEs cannot invest in their own expensive semiconductor infrastructure. When several actors make use of the same technology-intensive infrastructure, cleanrooms also support sustainable development.

Shared-use infrastructure enables small businesses to operate and provides large ones with an environment where they can e.g. experiment with new technologies and processes before initiating their own investments. VTT’s shared-use cleanroom facilities also serve as an open innovation environment.

VTT’s cleanroom was recently upgraded to fully support 200 mm wafer size, so it is now compatible with the wafer sizes used in many other European R&D cleanrooms. Thus, it now offers an even wider range of opportunities for its users than before.

In Finland and at VTT, we have succeeded in commercialising the shared use of processing capabilities and cleanroom facilities. At VTT, we have the capabilities to process several technologies: RF technology, MEMS, integrated photonics, microelectronics materials, integration technologies and superconducting quantum technology. We offer a comprehensive package in which usability has been considered from the customer’s perspective.

Extensive service package under one roof

With a single contract, the customer can flexibly access a wide range of processing capabilities under one roof. Companies can base their R&D activities on this environment.

VTT manages the maintenance of the cleanroom and its equipment and provides processing support and extensive R&D services for companies. The companies also hope that VTT would lead the way in new technologies and evaluate them for the benefit of others. VTT does this through its R&D activities.

VTT has a great social responsibility, as the choices it makes regarding the cleanroom processing capabilities largely serve as a basis for what kind of companies are established in the Otaniemi environment.

VTT has been investing in its infrastructure and equipment for decades. Their continuous updating and maintenance are essential. VTT’s cleanroom organisation, with more than 40 experts, takes even better care of the reliable maintenance of equipment and processes than research infrastructures in general. VTT has received support for developing the technology infrastructure from the Ministry of Economic Affairs and Employment, Business Finland and the Academy of Finland. However, VTT manages the maintenance itself, and the costs are covered by billing the cleanroom users. This applies to both companies and VTT’s own use in research projects, for example. For small players in particular, using VTT’s infrastructure is considerably cheaper than investing in one’s own.

In the early stages of their operations, enterprises can plan their business relying on the shared-use infrastructure. As companies grow, their need for manufacturing capacity increases, which means that they often invest in their own infrastructure. Following this, shared-use environments turn into R&D infrastructures, allowing companies to experiment with new technologies.