In a world racing toward sustainability, efficiency and innovation, material science is undergoing a transformation. One of the most exciting developments on the horizon is the emergence of Materials Acceleration Platforms (MAPs). These powerful MAPs are set to revolutionise how we discover, design and deploy materials. If you’re in manufacturing, product development or advanced R&D, this is a trend you don’t want to miss.

What are MAPs?

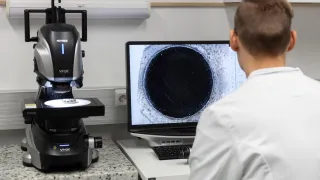

MAPs are integrated systems that combine experimental and computational techniques like high-throughput sample manufacturing, advanced characterisation, multiscale materials modelling and artificial intelligence. Rather than approaching material development in silos, MAPs orchestrate these diverse capabilities into a seamless, feedback-driven loop that accelerates the pace of innovation.

At their core, MAPs build on the foundations of Integrated Computational Materials Engineering (ICME). But they go far beyond simulation. By tightly connecting modelling with rapid physical testing and AI, MAPs enable near-instant learning cycles, slashing time to market and opening new frontiers in material design.

The big benefits of MAPs

The potential of MAPs isn’t just theoretical. Used right, they can reduce material development time by as much as 90%. What once took years of trial-and-error in the lab can now be done in months or even weeks.

But speed is just the beginning. MAPs also bring:

- Smarter decisions through data fusion:In addition to using experimental data to support the construction of models and formulation of modelling hypotheses, it is simultaneously used to validate the model’s accuracy and functionality. The data generated through modelling feeds into the design of targeted experimental work.

- Cost-efficiency and sustainability: Less prototyping and fewer failed tests mean lower development costs and reduced material waste. MAPs also make it easier to model the environmental impact of materials, supporting circularity and compliance with emerging regulations.

- Breakthrough products: MAPs are not just about optimisation. They make it possible to explore entirely new material combinations and performance spaces, enabling true market disruption. From next-generation battery chemistries to recyclable polymers and ultra-durable metals, MAPs unlock possibilities that were previously out of reach.

Why act now?

The urgency of global challenges, from resource scarcity to climate change, is driving demand for better, greener materials across every sector. At the same time, digital technologies like AI and high-performance computing have matured to the point where they can truly accelerate materials R&D.

This convergence makes MAPs not only possible but essential. They offer a strategic advantage for organisations aiming to innovate faster, meet regulatory demands and lead in the green transition.

VTT is leading the way on MAPs

At VTT, we’ve been pioneering advanced material development for over 20 years. Utilising VTT ProperTune multiscale materials modelling technology we're helping companies shorten their development time for new material solutions by 50% or more. With the development of MAPs, we're scaling that impact even further.

Don’t let your innovation pipeline get stuck in the past. MAPs are here – and they’re reshaping the future of materials. Read our white paper on MAPs here and contact us to get things started!