VTT’s TOF-SIMS device is a new reinforcement to Finnish materials research. The device is capable of studying the surface composition and durability of solid materials, such as those used in hydrogen engines, semiconductors, and fusion reactors. Not only VTT researchers and partners, but also companies’ product developers, have access to this device.

Read the summary

- Valued at €1.3 million and partly funded by the Research Council of Finland, the device will support sectors like microelectronics, metal industries, and hydrogen technologies with detailed elemental data.

- As a rare, advanced instrument, TOF-SIMS strengthens VTT’s capabilities in analyzing materials for hydrogen tech, lithium batteries, and fusion reactors, aligning with European standards and boosting industrial innovation.

This summary is written by AI and checked by a human.

VTT has obtained Finland’s first TOF-SIMS device for chemical surface analysis. This instrument is unique in materials research because it can analyse all the chemical elements present in a sample, including hydrogen.

“This instrument will provide us with crucial information on materials in key industrial product development areas in Finland. I consider it a national asset for Finland, and we will offer analysis services to companies as well,” says Jari Likonen, Principal Scientist at VTT.

He believes that the device will yield groundbreaking results. The significance of the instrument is evident from the fact that no other method besides TOF-SIMS analysis can provide three-dimensional and precise data on the elemental composition on the surface of a material sample or detect hydrogen in microstructures of metals.

“Basically, the sky’s the limit when it comes to application areas. The primary target group seems to be microelectronics, as researchers in that field have already submitted samples. We have also received samples from the metal industry for biocorrosion research. Other significant application areas include hydrogen technology, lithium-based batteries, electric vehicle chargers, fuel cells and fusion reactors,” explains Likonen.

Materials research at VTT continues its modernisation with a device investment worth over a million euros

The new device is the next step in modernising VTT’s materials research equipment to meet the highest standards in Europe and the Nordic countries. The previous similar procurement was a plasma FIB scanning electron microscope, which was put into use at the end of last year.

Expensive TOF-SIMS devices are rare, with only a few hundred of them worldwide. The German device purchased for VTT cost approximately EUR 1.3 million. The Research Council of Finland funded about 52 % of the investment costs, with VTT covering the rest. The procurement was organised by the H2MIRI consortium of the Finnish Research Infrastructure Committee FIRI; the consortium includes not only VTT but also the universities of Oulu and Tampere.

“In addition to conducting analyses for the consortium members, we will also provide analyses as a service. A specialist is still needed to operate the instrument and analyse the results. VTT has a team of six people with the necessary user training,” says Jari Likonen.

Vastly useful for semiconductor, metal and hydrogen technologies

The usefulness of TOF-SIMS is evident in applications such as semiconductors and microelectronics. In these applications, it is crucial to precisely determine the depth distributions and quantities of different elements in material layers because they impacct electrical properties. Likonen says that this specific information cannot be accurately obtained using any other technique besides TOF-SIMS analysis.

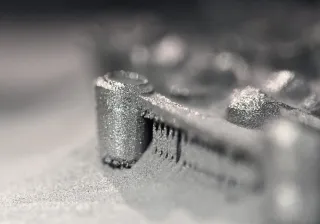

Research on the coatings of metal products is also necessary as impurities can reduce lifetime of the components. For instance, drill bits will wear out quicker if the special coating designed to enhance durability does not adhere properly.

Green hydrogen production technology, which is of significant commercial interest in Finland, requires analyses because hydrogen can make materials brittle.

Likonen emphasizes, “Hydrogen buildup in metal can significantly impact the lifespan of machinery or engines. It is essential to study the corrosion resistance of manufacturing materials before producing an engine,” Likonen is coordinating research on the first wall materials of the JET fusion reactor located in England; which will also require TOF-SIMS analyses in Otaniemi. The fusion reactors are hydrogen-powered, and the surface materials must withstand extreme heat, even though the hydrogen plasma is separated from the materials using magnets.

Ion time-of-flight reveals the precise composition of materials

The name of the device directly reflects its operating principle. The acronym, TOF, stands for “Time-of-Flight”, while SIMS stands for “Secondary Ion Mass Spectrometry”.

“The device measures the time-of-flight of each ion in a vacuum. Using this data, the software calculates the exact elemental composition based on the mass and charge of the ions,” explains Jari Likonen.