The Made In Europe partnership is halfway through its operation. It has already proven to advance innovating in the manufacturing industry and will continue until 2027. VTT has a central role in the partnership by virtue of its co-chair position.

In the fall of 2021 we wrote about the Made In Europe (MIE) partnership, part of the Horizon Europe framework program. VTT’s professor of practice Riikka Virkkunen had just been nominated as the co-chair of the partnership. The partnership is active in the years 2021-2027 so it is time for an interim review and a brief look at what is still to come.

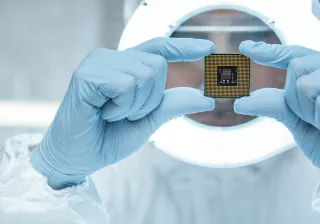

Manufacturing industry is in the heart of European economy and it is extremely important to foster this. The ecosystem of manufacturing industry is very rich and contains the whole chain starting from individual manufacturing methods all the way to mastering complex value networks. Applications range from metal processing to producing bio-based products. For this reason also the needed technologies are diverse and challenges interdisciplinary. Joint projects and broader partnerships spanning industry sectors and country borders are essential in order to achieve the best possible results.

MIE objectives support Europe’s manufacturing industry

The MIE partnership has a budget of approximately one billion euros. Its strategy focuses strongly on advancing the competitiveness of European manufacturing industry and improving its innovativeness. At the same time green transition and circular economy are at the core of its agenda. One central theme is resilience, meaning the organizations’ capabilities in adapting to fast and significant changes in their operating environments.

By the fall of 2023 first projects funded by the MIE partnership have already been launched. VTT and Finnish companies are involved in projects, which for example accelerate the usage of artificial intelligence and 5G in production, manufacturing innovations for bio-based products, zero-defect and emission-free manufacturing of metal products, and implementing circular economy strategies.

MIE partnership projects and several interesting results are listed on the portal of EFFRA (European Factories of the Future Research Association, Made in Europe’s official private partner). The portal also functions as a channel to find partners to new joint projects.

Finnish companies benefit from the MIE partnership in several ways

While first projects have just started, the partnership plans the activities for its final years. At the moment the objectives for years 2025-2027 are on the table. According to Europe’s Green Deal strategy and accelerated by the energy crisis, circular economy and climate-neutral themes will stand out. Innovations and capacity needed for manufacturing clean energy devices is particularly important. Also the resilience of manufacturing chains has become more relevant because of the pandemic and the geopolitical situation.

The partnership has created an excellent opportunity for VTT to do good for Finnish companies. The partnership opens doors for the companies to go international. Its main task is to focus the research themes so that they are based on the companies’ needs. In addition, the companies are very welcome to contribute themselves either by becoming members of EFFRA or by taking part in working groups, surveys, and projects.

Manufacturing industry’s long-term objectives are to grow in a sustainable manner and offer rewarding jobs. Europe should support the innovation capabilities of manufacturing industry, because it has strategic impact for example in business, environment, and wellbeing of the society. EFFRA plays an important role in this and VTT has the best imaginable place right there in the middle of activities. The future of manufacturing industry is being made in Europe!