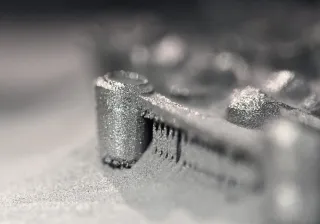

While no useful further use has yet been found for dust bunnies collecting in the corners of households, VTT developed a reuse for zinc-containing dust produced as a side stream from the steel industry.

Such dust contains small solid particles that hang in the air and slowly settle on surfaces. If inhaled, it may have significant adverse health effects. The finest material is usually the most difficult to treat and recirculate.

The steel industry's side streams in Europe generate several thousands of tonnes of zinc-containing dust waste each year, which, at its worst, is treated as hazardous waste. The treatment of hazardous waste is very expensive and the environmental load created by it is high.

In the industry, fine dust can already be collected carefully at the process stage, but the dust thus collected, including hazardous waste, has been challenging to process further. Studies conducted by VTT have shown that dust collected at steel plants is of interesting composition and suitable for granulation/pelletisation. By combining these two features, an advantage for the side stream in question can be created, as the treatment process of the side stream into a new product is simple and affordable.

Dust from hazardous waste generated in the steel industry set to improve the biomass treatment process

Imagine a chain where dust waste generated as the side stream at a steel plant can be used as a functional material in another application. In VTT's innovation, such hazardous waste becomes a product that is both cost-effective and environmentally friendly.

Elsewhere, zinc oxide is used to absorb sulphur in the gasification of biomass. Zinc oxide has an excellent ability to bind sulphur from gas mixtures containing it. It is estimated that in the future, as much as 5,000 tonnes of zinc oxide will be needed in Finland alone to bind the emissions released by the gasification of biomasses.

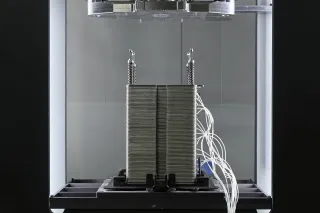

VTT has shown in laboratory tests that side streams containing zinc originating in the steel industry can be used to remove sulphur from the biomass gasification process almost as efficiently as using the current commercial zinc oxide products.

The future challenge of this potential raw material based on a side stream, now proven feasible, is to create new business activity, i.e., to transfer the process to an industrial scale in a cost-effective manner. In this context, a 3-year project (2020-2022), funded by the EU EIT Raw Materials, is under way, aiming at bringing the sulphur-binding material now developed to the market.