Fibre materials technology

The demand for sustainable and renewable materials is increasing. With VTT you can create new bio-based materials viable for the circular economy and methods for manufacturing them more efficiently.

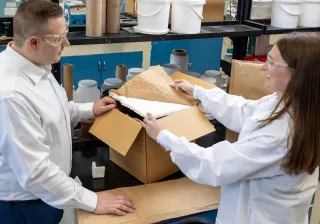

The market demand and legislative requirements for sustainable and renewable materials are increasing fast. With VTT you can create new bio-based and plastic-free materials for the circular economy and develop methods and processes for manufacturing them more efficiently.

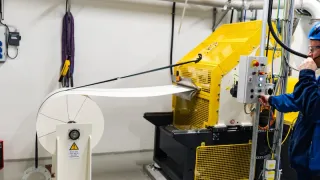

The fibre materials technology platform allows you to experiment and develop new fibre-based material solutions for packaging, construction, nonwoven and hygiene applications. Let it be cellulose based, biopolymer or any kind of fibre raw material.

Scaling new opportunities from laboratory and R&D to commercial production always benefits from validation and testing in relevant scale, and our pilot facilities provide comprehensive research capabilities tailored to industry

requirements. Minimize the risks with our existing infrastructure and support your decisions with data gathered with our advanced measurement and sensor data collection.

VTT’s research infrastructure for fibre materials includes advanced laboratory facilities and three unique pilot lines. Alongside the traditional wet-laid process, we offer foam forming and airlaid technologies. Our expert teams complement this infrastructure with comprehensive support and know-how, ensuring a complete service package. The pilot facilities are in Jyväskylä.

Our key infrastructure:

- Paper, board and nonwoven pilot lines

- Foam forming piloting

- Airlaid piloting

- Sustainable fibre product piloting

- Nonwoven technology and material development

- Analysis laboratory for fibre and nonwoven products

- Multiphase flow laboratory

- Rheology laboratory

- Web forming laboratory

- Water foam and air-laid web forming laboratory

We provide:

- Pilot and laboratory scale material and process development

- Product and process development

- Networks for full scale commercial projects

- Consultation support on business cases, related process modifications and new product innovations

For:

- Paper, board, tissue and nonwoven producers

- Machine suppliers

- Chemical suppliers

- Raw material suppliers

- Brand owners

Examples of development areas enabled with our piloting equipment:

- High solid contents, up to 10 times higher

- Multiple fibre options, diverse pulp sources and textile fibres incuding recycled fibres

- (Multi) Layered thick structures

- High running speeds

- Savings in energy and water usage