Concrete is a wonderful material, but also one of the biggest emission sources. In 2018, the global cement industry accounted for approximately 8% of the carbon dioxide emissions and up to 20% of industrial emissions worldwide. We are seeking solutions for the emission problems caused by concrete production, carbon-neutral manufacturing not being the least of them.

We have concrete all around us − in buildings, bridges, pavements − even in the foundations of wooden buildings. Concrete and its main raw material, cement, can be easily modified, and there is no serious contender for their versatile range of uses.

A lot of work has already been done for reducing emissions by focusing on energy efficiency of production. In terms of average need of energy per tonne of cement produced, Finland does very well in international comparison. However, improved efficiency alone will not suffice, and therefore the manufacturers of cement and concrete products all over the world already have their eyes fixed on other measures. Finland is committed to reaching carbon neutrality by 2035, but in order for Finland to reach the goal, rapid action is also required from the concrete industry.

Carbon dioxide is released when the main raw material of cement, limestone, decomposes in the temperature of about 900 °C. The decomposition, or calcination reaction, of limestone caused by heating produces quick lime, used as raw material for cement, and releases a significant amount of carbon dioxide. The amount released corresponds to about a half of the carbon dioxide emissions from cement production. The emissions generated by cement production cannot be avoided, but the heat used for the process can be produced in a sustainable manner. Compared to calcination, the even higher temperature of approximately 1450 °C, required for generating reactive clinker phase in cement manufacturing, adds challenge to finding alternative heat sources.

How to reach carbon neutrality?

Hot and stable temperature can be sought, for example, by replacing fossil fuels with bio-based alternatives or by electrifying the rotary kiln used for calcination. As a by-product, the latter of the alternatives produces pure carbon dioxide, which is a major advantage for further use. Rotary kilns are employed by other important areas of industry as well, and there is currently a lot going on in the development related to industrial electrification. VTT is currently studying alternatives towards a low-carbon industry with several Finnish corporate partners from various sectors in the Decarbonate project funded by Business Finland.

Let’s turn disadvantage into advantage: carbon-cured concrete

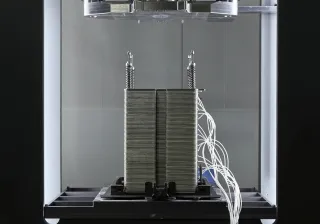

At VTT, we have started to develop carbon-cured concrete: in carbon curing, concrete is cured with gaseous carbon dioxide, from the plastic phase forward. The curing of concrete with pressurized carbon dioxide generates not only the ordinary reaction products of cement but also carbonate-based reaction products. Consequently, the process binds carbon dioxide, and it is even possible to make the final product carbon negative if ordinary cement is replaced with alternative binders with a low carbon footprint. We have been developing carbon curing for the last year in the CO2Crete project, using simulation-based optimization and LCA calculation.

In the tests conducted in the project, with pieces made of Portland cement the carbon footprint achieved was 10−40% smaller; carbon neutrality was achieved using blast-furnace slag and carbon negativity using a mix of slag, green liquor dregs and bark ashes. The optimal mixture ratios with a view to carbon curing were examined with the help of thermodynamic modelling, for which VTT developed a tool for a wide spectrum of raw materials during the project. The method has produced promising results not only in carbon binding, but also in terms of strength, which is a crucial property for durable concrete.

These results and other developments were presented at VTT to an audience representing the concrete and cement industry, construction sector, research community and various Finnish ministries at the Carbon-neutral Finnish concrete industry by 2035-seminar held in November 2019.

And there’s more

The range of actions aimed at reducing emissions is wide. All these are necessary if we want to reach carbon neutrality: recycled raw materials, alternative binders, waste reduction, extending the life cycle of buildings and construction requiring less material.

Legislative steering is one of the most important ways of influencing matters, since it helps create preconditions for actions and set requirements for operators. Good legislation needs to be supported by industry and innovations. We should pool our resources through closer alliances and share topical information. We can create competitive advantages and operational agility by means of functional cooperation and ecosystems.

Sustainable business always operates on the terms of the economy and, increasingly, under the hard pressure from the global markets. The concrete industry is no different from other sectors in this respect. In other words, we need to reflect all our actions against the economy, and the analysis behind the economic indicators must be based on correct source data and as probable vision of the future as possible.

The other factors that have emerged by the side of economy are safety and accountability. Together, these three constitute the foundations of competitive business: you cannot afford to make compromises on any of them.

Global trends often force the world to change faster than legislation. When we know that, in a changing world, it is slow to develop new technologies and it is a challenge to attract investments for such development, the collaboration between companies and research institutes bears fruit. We must remember that the changing world is not only a threat, but also an opportunity.

If either carbon-cured concrete or industrial electrification caught your interest, don’t hesitate to contact experts at VTT.