It is fair to say that we are sitting on a gold mine with endless possibilities to choose from when it comes to protein-based materials. They form the richest classes of high-performance structural biomaterials in nature and offer more sustainable alternatives to synthetic materials. There is a simple reason why we often associate protein-based materials with prefixes such as “super”, “extraordinary”, and “high-performance”: when it comes to performance, they surpass most of their man-made counterparts. So, the question is, can we imagine a future where we could use such materials to make our day-to-day use items or high-tech applications? Can we become truly independent from synthetic plastics one day?

The pressing problem with how we use materials today

Petroleum-based polymeric materials transformed our way of living in the 20th century. Today they are intricately linked to all aspects of modern societies and technologies, contributing to countless essential goods in our daily life. While this has brought many benefits, their fabrication and disposal has also created widespread ecological catastrophes. Thus, there is a pressing demand to develop more sustainable solutions that will mitigate these issues and call for radical transformation.

The radical solution

Nature has countless examples of biopolymers being synthesized using the complex machinery of living cells. We have much to learn from such materials. Natural biopolymers, i.e. proteins, are made of naturally occurring building blocks, processed under benign environmental conditions, and their degradation is harmless as nature has adapted strategies for their complete decomposition through the course of evolution. More often than not, biological materials are also multi-functional. An example of this are mussel fibers: a single byssal thread is both stiff and extensible and contains multiple adhesive proteins for efficient underwater attachment as well as a hard proteinaceous coating.

The molecular designs unveiled in the past decades for many of these biological materials offer countless opportunities to design a whole new range of biopolymers from the bottom up. By combining building blocks from multiple model systems in a modular fashion, the range of achievable mechanical and physicochemical functional properties can be broadly expanded. This could, in principle, enable the fabrication of truly multi-functional materials that never existed before.

What tools do we need to produce protein-based materials?

In the field of industrial biotechnology and synthetic biology, artificial production of many of these protein-based materials looks to be feasible with the emergence of start-up companies. Biotechnology and genetic engineering are indispensable tools in our quest to harness the molecular designs of natural biological materials and replicate them synthetically, enabling the production of biopolymers with single molecular precision and mono-dispersity.

In the past decade, some of the most noticeable improvements in the field have been the cost and speed of gene synthesis. Other important advancements in the field have been the integration of laboratory automation and one-step precision cloning techniques. Combining these with the access to a substantially large selection of expression hosts, the chance of successful expression of any orthogonal genes has never been greater. The bottom line is that we can accelerate the sustainable production of novel protein-based materials of the future using synthetic biology and industrial biotechnology.

Remaining challenges ahead

There are several challenges ahead before artificial protein-based materials can replicate the described model systems and become a reality in daily life applications. One of the primary challenges due to complications depends on the complexity of the gene, sequence length, transformation efficiency, stability of cloning-expression vectors, and cloning-expression host. To overcome some of these challenges of expressing difficult proteins, metabolic engineering of the expression host using synthetic biology toolkit is a favored option to improve the yield and quality of the desired proteins. This has never been a more attractive option as we have full access to the entire genomes of almost all the expression hosts and their sub-variants but also state-of-the-art gene editing techniques such as CRISPR/Cas9, as well as larger-scale and programmable chromosome fusion which can target thousands of genes at once.

These exciting enabling technologies, such as state of the art gene editing techniques, could result in the creation of completely new synthetic hosts that could be programmed and specifically designed to express the target proteins. Current microbial fermentation processes mainly involve the conversion of readily available carbon sources, such as plant-based simple sugars and starch, into chemicals, fuels, and biopolymers. One alternative solution is to exploit biological conversion of low-cost CO2 to high-added value chemicals and energy. Latest advances in synthetic biology are forecast to offer new tools to improve the properties and artificial production of these materials.

Towards the next generation of biopolymers

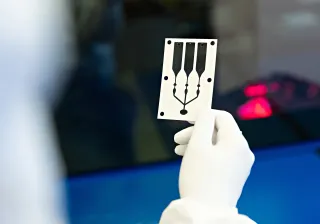

Future research will require engineering and utilization of entirely new and novel microbial strains to fabricate complex biopolymers that are interlinked to semi- or fully automated high-throughput platforms for process optimization, advanced material fabrication, and characterization. We are also entering an overly exciting new era of machine learning and advanced computational modeling. This new in silico toolbox may provide a wide source of data-driven inquiries as well as exciting applications in protein polymer design and manufacturing, for example, to enhance metabolic engineering to optimize yields and the final product design.

VTT’s Senior Scientist Pezhman Mohammadi and his colleagues from Nanyang Technological University and Institute for Digital Molecular Analytics and Science, Singapore published a comprehensive review related to this blog post in Chemical Reviews.

Read the article here: Protein-Based Biological Materials: Molecular Design and Artificial Production