Agriculture is a major contributor to environmental pollution. It is also a notoriously challenging industry to decarbonise. Meanwhile, emissions from maritime transport are accelerating globally. But there is a somewhat unexpected solution to reducing the climate impacts of both agriculture and shipping – good old ammonia, produced in a new sustainable way.

What is green ammonia?

Ammonia is a chemical compound derived from hydrogen and nitrogen. Not only is it widely used in the production of agricultural fertilisers, it is also an indispensable chemical for many industries. The production of hydrogen, and therefore, of ammonia, is traditionally based on natural gas.

Ammonia produced by traditional methods is called grey ammonia. Green ammonia, in turn, refers to ammonia produced without emissions using renewable energy sources, such as solar or wind power. The outcome is a substance with the same composition and use as grey ammonia.

Green ammonia is a sustainable alternative for different energy needs

Ammonia is carbon-free. Therefore, combusting it doesn’t produce carbon dioxide emissions, only water vapour and nitrogen. This makes ammonia a promising alternative for energy production, as its large-scale use could have substantial positive climate impacts by reducing reliance on fossil fuels.

In this blog post, we will explore three practical applications of green ammonia. However, its potential in energy production is vast and, to an extent, untapped.

Green ammonia in shipping

The potential of green ammonia has been predominantly discussed in the context of shipping, as the maritime industry is constantly searching for new ways to enable carbon-neutral transport. Maritime transport accounts for approximately 3% of global greenhouse gas emissions.

Green ammonia is considered as an alternative to replace diesel as a marine fuel. Another green fuel option is renewable methanol. Before this becomes possible, we need clean electricity production and new technology for ships and refueling stations. Fuel must be widely available – initially at specific locations and later in every port in every country. This is paramount for ensuring the solution's efficiency and the operation of long-distance vessels.

There is also the question of whether to build hybrid ships that use green methanol and ammonia as fuel or whether separate ships are required for each fuel. We still have technical challenges ahead of us, and the transition won’t happen overnight.

Green ammonia in agriculture

Around 80% of industrially produced ammonia is used to produce nitrogen fertilisers. These fertilisers increase the amount of nitrogen in soil, as nitrogen is an essential nutrient for plant growth. Ammonia is and will continue to be an irreplaceable raw material for food production.

Many countries are currently dependent on imported ammonia. Producing green ammonia with renewable electricity would be a step toward becoming fully self-sufficient in fertilisers. Domestic production could also bring new export opportunities.

The large-scale use of green ammonia could have substantial positive climate impacts by reducing reliance on fossil fuels.

Ammonia as an energy carrier

One of the key benefits of ammonia is its energy storage capacity. Transporting hydrogen over long distances can be challenging, but ammonia can be used as a hydrogen carrier. Hydrogen is bound in ammonia on molecular level, and ammonia can therefore be used for the transportation and storage of hydrogen.

Japan, for example, is considering whether the country’s energy supply could be based on imported ammonia. The country has traditionally depended on natural gas and coal and is now looking for alternative solutions.

New challenges require a new mindset

Green ammonia has enormous potential, but there are still some challenges to overcome. One of them is creating a new infrastructure. Ammonia is a highly corrosive substance, so it’s not as easy to handle and store as the fuel oils currently in use. Therefore, we must rethink material choices, storage temperatures and transport practices, and develop safe ammonia production and use techniques. However, all these obstacles can be overcome – green ammonia just requires a slightly different mindset.

Our goal is to organise an industrial-scale pilot in Finland to demonstrate clean maritime technologies and solutions. The most important thing is to unite the maritime cluster behind a common goal.

Finland leading the green way

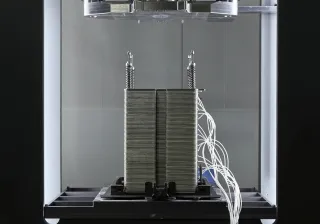

There are several market niches for green ammonia. At VTT, we are currently developing technology pipelines for the entire ammonia value chain – from system management and hydrogen production through to the end-use of the product. We are also involved in several collaborative projects with different companies.

Finnish maritime know-how is founded on shipbuilding and maritime technology. We have a wealth of expertise in all stages of shipbuilding – from engines to ship design and construction.

Our goal is to organise an industrial-scale pilot in Finland to demonstrate clean maritime technologies and solutions. The Finnish archipelago would be an ideal location for the pilot, as we have renewable electricity, hydrogen, and high-occupancy vessels with defined routes. This experiment could be based on one or more clean fuels. The most important thing is to unite the maritime cluster behind a common goal.

In addition to rapidly increasing green power production capacity, Finland has forward-thinking companies and an agile culture ¬– all of these are essential in a changing society. Whenever new solutions are required, we, as a ‘nation of engineers’, can certainly create them.

If you are interested in the potential of green ammonia and related collaborative projects, please don’t hesitate to contact us.