Microelectronics solutions beyond the mainstream CMOS

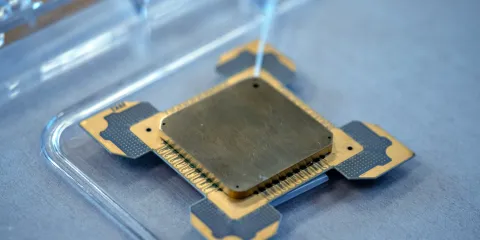

Microelectronics components are the foundation of today's digital systems. They enable the devices and networks essential to modern life. The world’s increasing tech needs require the development of new microelectronics that combine enhanced performance with lower energy consumption. This drive for sustainable development is sparking innovations in microelectronics. VTT is at the forefront of developing these innovations, including new materials, advanced processing, component integration and inventive device designs.

Key facts

We focus on solution development for 6G and medical applications. We incorporate sustainability into our R&D process at five levels: manufacturing, material development, device design, system architecture and application selection.

Thanks to our in-house semiconductor R&D cleanroom, we support you all the way from concept innovation to small-scale manufacturing. We also have unique in-house material modelling and development capabilities for next-generation microelectronics solutions and processes.

Our IPR portfolio includes over 140 patent families related to microelectronics that are available for licensing.

Figure: VTT’s five-level sustainability approach – we consider our choices in all these areas.

Video: Shaping a brighter future with microelectronics

The need for innovative components is increasing

Microelectronic components are the key enablers of nearly every product or service that we use daily. The sensors in our phones and cars are familiar to everyone, but as the world becomes smarter and more interconnected, the need for innovative components increases. Each new development can help us improve efficiency, productivity and ultimately the quality of our lives.

We offer a unique, fast and cost-effective path to support our customers’ product development – from microelectronics R&D to piloting and small-scale manufacturing.

A legacy of innovation in nano- and microelectronics and MEMS

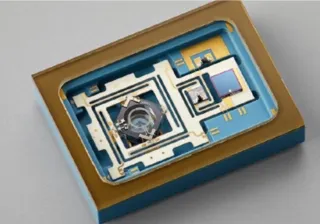

We are an innovator in the field of microelectronics and a central player in shaping the industry, both in Finland and internationally. Our know-how has enabled us to be pioneers in developing novel micro-electro-mechanical systems (MEMS), photonics integrated circuits and quantum technology and other specialised components used to create a wide range of sensors and devices.

We have been designing innovative RF components for mobile telecommunications since the industry's early days. Our work in quantum technology and 2D materials continues our tradition of operating at the cutting edge of nano- and microelectronic component development.

We are a pioneer in creating innovations, including:

- Acoustic RF filter development since the 1990s. Our BAW technology is still in use in today’s mobile devices.

- Superconductive materials and device development since the 1990s

- Cryogenic CMOS for quantum applications

- Piezo MEMS development for over two decades

- Unique Fabry-Perot interferometer technology for hyperspectral imaging used in handheld, airborne and space applications

- Low-loss integrated photonics solutions for sensing and communication

- Integrated RF solutions from MMICs to Massive MIMO antennas and front-ends

- New materials and functionalities for post-CMOS integration of novel computing and sensor solutions

- 2D material-based devices including graphene for biosensing

Our services

VTT offers research and development of new materials, technologies, devices, systems and processes. Our 200+ R&D experts are ready to help you create new microelectronics solutions using our in-house and external technology platforms, IPR and expertise.

We can provide the entire development cycle, from feasibility study and fundamental research to prototyping and small-scale manufacturing. We have capabilities to integrate different technology platforms and create unique solutions including MEMS, photonics integrated circuits, quantum and other specialised components, RF devices as well as 2D materials.

Get in touch with us to harness our tailored services:

- Research and development services

- Application specific material modelling and development

- Device and process design and innovation

- In-house manufacturing, prototyping and piloting

- IP licensing

Related infrastructure

How to work with us in your nano- and microelectronics projects

-

Contact us!

Tell us what you want to do, and we will figure out how to do it. No project is too small or too ambitious – we would love to hear from you. After the initial assessment, we might be able to offer some of the following options.

-

Customised partnership

Every research case is unique, and we’re happy to tailor our services to your needs.

-

Cooperative project

We frequently participate in research and development projects with multiple business partners and funding agencies. In cooperative projects the risk is split between multiple organisations, and everyone benefits from the results.

-

Our networks at your disposal

We are happy to put you in touch with the ideal sparring and development partner.

Meet our experts

Ecosystems offer superior networking

As part of our leading role in the latest nano- and microelectronics developments, we are proud to participate in various ecosystems, both in Finland and worldwide. Through these networks, you gain access to the latest industry trends.

- Semiconductor group of Technology Industries of Finland

- The Heterogeneous Technology Alliance in Europe together with CSEM, Fraunhofer and CEA-Leti

- European Association on Smart Systems Integration EPoSS

- SEMI, the microelectronics industry association

- AENEAS Sinano

We are also an active player in large European research programmes.

- We are part of the PREVAIL project, focused on building an EDGE AI pilot line in Europe. Our aim is to build up capacity for back-end-of-line (BEOL) manufacturing.

- We are also part of the EU graphene flagship project, which focuses on building a 2D experimental pilot line in Europe.

VTT spin-offs scale up innovations

Our research has resulted in several spin-off companies such as SemiQon, Spectral Engines and Kyocera Technologies.