Battery technologies

Batteries play a key role in the ongoing shift from the use of fossil fuels towards sustainable transportation and renewable energy production. In today’s world, we need more high-performance, lightweight, safe, low-cost, and sustainably sourced and manufactured batteries to power the electric vehicles in a sustainable way.

Key facts: Battery research at VTT

VTT can characterize energy storage devices in small and large scale, and develop battery management systems for them

Our goal is to increase the sustainability of batteries by developing new materials and manufacturing & recycling methods, and by increasing the lifetime and energy density

We test and develop new battery manufacturing processes both in lab and pilot scale

We also need to guarantee ethical raw material sourcing and take the limitations in the material availability account. This creates a clear need for efficient recycling and tracking solutions, novel battery chemistries and methods to increase the battery lifetime.

The electrification of harsh-use applications such as heavy-duty vehicles, non-road mobile machinery, and marine vessels also provides big potential for increasing the energy-efficiency and performance as well as decreasing local emissions. The advantages from this are for example improved productivity and user experience, and lower total cost of ownership.

In addition, the increasing need for sustainable solutions for stationary energy storage creates opportunities for new battery technologies.

Portable and wearable electronics require specially designed energy storage components to allow safety, sustainability and new form factors for the batteries.

Our service in brief

We can provide help with requirement specification, technology assessment and selection, systems engineering, BMS and energy management, grid integration, battery health monitoring and prognostics, lifecycle management, sustainability assessment, and how to use the battery in the application in an optimal way to ensure that the battery remains healthy and its lifetime is maximized.

In addition, VTT can support the battery sector to test and develop novel battery materials and manufacturing processes, even in pilot scale.

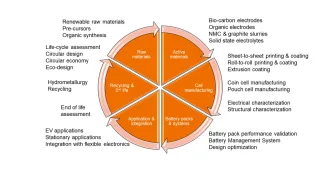

VTT can support research and industry within the whole battery value chain

The following image and photographs describe our main activities in the energy storage field, throughout the whole value chain and in a circular economy fashion.

Applied battery research facilities

We have developed competences and facilities for applied energy storage R&D since late 2010. Our research laboratories enable comprehensive experimental work on battery cells, modules and packs, as well as battery management systems and thermal management. These facilities are integrated with dynamometer facilities enabling experimental work not just on batteries, but also on heavy-duty vehicles, drivetrains, and engines under the same roof. And with our high-power battery emulator, we can test electric vehicle prototypes on the dynamometer even without a real battery installed in the vehicle.

We also have world-class battery testing facilities for performance and lifetime testing of commercial large-format cells, modules, and packs. We have tested hundreds of batteries, and therefore, we can provide state-of-the-art knowledge, foresight, and experimental research services. The backbone for these services is the experimental work combined with modelling capabilities and tools.

Related infrastructure

VTT has both laboratory and pilot scale facilities where we can print and coat different battery materials and layers.

Next generation batteries

Our aim in the next generation battery field is to find solutions to cope with the increasing energy storage need and limited material availability. To achieve this goal, we develop energy storage devices, which utilize sustainable materials like biocarbon. Such batteries would be optimal for stationary energy storage where high energy density is not the most important parameter. In addition, we aim to manufacture long-lasting and safe solid-state batteries, or even flexible batteries. These batteries would be suitable e.g., for electric vehicles and wearable electronics.

We can offer a platform to test both standard and novel battery processing methods and help to upscale the production. In addition, VTT has the capability to assemble both coin and pouch cells in inert atmosphere. Our unique printed intelligence facilities and knowhow enable the integration of batteries with other components, such as solar cells, sensors, and LEDs.

Videos on battery technologies

Sustainable battery development at VTT

Electric vehicles and battery technologies

Projects

- VTT coordinates a Battery 2030+ H2020 project about self-healing batteries

- VTT participates in two national projects to develop manufacturing of solid-state batteries

- VTT participates in a national project to develop methodology for optimal use of batteries in non-road mobile machinery

- VTT participates in a national project to develop recycling of Li-ion batteries

Downloadable materials

Meet our experts

Dr. Ari Hentunen is a Research Team Leader at VTT. He holds a DSc (Tech) degree from Aalto University. He has worked for over 15 years with EV technologies and battery storage systems, and he has strong knowledge in the experimental performance characterisation of lithium-ion batteries as well as electric vehicle technologies. Dr. Hentunen’s main interests are performance and lifetime characterization of batteries, grid integration and operational optimization of battery storages, and battery management and health diagnostics. He has been a project manager and work package leader in several research projects at European and national level. He is a member in BEPA TWG3 & TWG4 and Batteries Europe WG5 & WG6, and he contributes to EERA JP ES SP1 & SP6.

Dr. Marja Vilkman is a Principal Scientist at VTT. She has a MSc degree in chemical engineering and DSc degree in physics, both from Aalto University. Marja has worked with functional materials and their processing for 20 years, focusing recently on the energy storage applications. She develops materials and processing methods for sustainable next generation batteries, such as solid-state batteries and batteries that use more abundant or even bio-based materials. Marja is currently a coordinator of two EU projects, HIDDEN and SOLiD, which aim at producing Li-metal batteries with long lifetime and high energy density. She is also the research chair of the BEPA Working Group of Raw Materials and Recycling.

Publications related to battery technologies

We have a large database of publications in our research portal Pure. Find peer reviewed publications related to battery technologies by clicking the button below.

Contact us here!

Towards sustainable electronics

At VTT, our goal is to set a new standard for sustainability in the electronics industry and offer solutions that increase circularity at every stage of the electronics life cycle. Explore:

- Five ways to improve sustainability of electronics

- How to create new business from sustainable electronics?

- How to reduce electronics waste with sustainable printed electronics?