Hyperspectral imaging

Hyperspectral imaging is to photography what photography was to painting – a revolution. It allows us to detect what the eye cannot see. Hyperspectral imaging captures light intensity from a wide range of wavelengths within the electromagnetic spectrum and translates it into valuable information for an infinite number of applications ranging from healthcare to satellites.

Key facts

Hyperspectral imaging identifies the chemical composition of an object. The technology can be integrated into a variety of devices, ranging from mobile phones to nanosatellites.

We provide hyperspectral camera technology with high spatial and precise spectral resolutions tailored for a wide range of applications and price ranges.

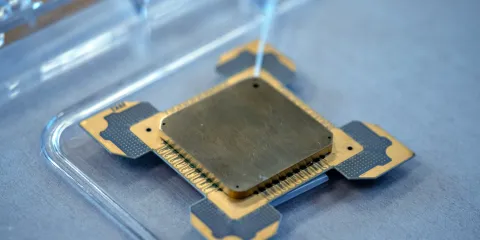

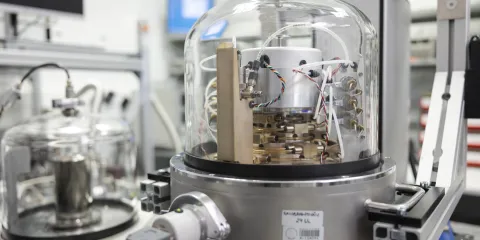

We have developed a unique, software-programmable, tunable Fabry-Perot filter technology, allowing us to offer a customised spectral measurement with the highest spatial resolution in the market.

Why hyperspectral imaging is a game changer

With hyperspectral imaging, we can identify objects and phenomena by their distinctive spectral signatures, which exist in virtually everything.

By taking us beyond the limitations of the red/green/blue colour space of modern photography, hyperspectral imaging cameras unleash new opportunities, from material differentiation to detecting biological processes in humans and the environment. It can provide materials identification for problems such as skin cancer, dehydrated plants or a fraudulent wheat grain batch.

Hyperspectral imaging has the potential to benefit nearly every area of human activity, whether by enhancing sustainability or opening up new avenues of exploration.

Hyperspectral imaging benefits a vast range of fields

- In the food sector, it helps with food safety and quality assessment.

- In healthcare, hyperspectral imaging is paving the way towards lean, fast and non-invasive optical biopsy, improving the early diagnosis and outcome of, for example, cancer.

- In the recycling sector, it allows to sort and valorise waste (e.g. plastics) much more efficiently.

- In mining, hyperspectral technology supports mineral identification and mapping of the run-of-mine, thereby promoting more sustainable practices through optimised extraction locations and reduced carbon footprints.

- Other sectors that benefit from hyperspectral imaging include, among many others, cosmetics, forestry, agriculture, environment monitoring, defence and space exploration.

VTT is a one-stop shop for your hyperspectral imaging needs

Our experts span multiple disciplines, and our deep knowledge of industrial applications means we can tailor our hyperspectral imaging technologies to your requirements.

Our know-how covers the entire research and development chain, including:

- Component design and fabrication

- Mechanical, optical and electronics design as well as software development

- Tailored prototyping and proof-of-concepts

- Application development

- Support with product development.

VTT, a pioneer in spectral imaging technologies since the 1990s, provides both the hyperspectral technologies and the solutions.

Video: Seeing beyond the obvious with high performance imaging technologies

Our hyperspectral imaging offering

Our hyperspectral cameras are fully programmable. This enables:

- Selection of the type and number of bands needed

- Faster analysis

- Enhanced sustainability by optimising data storage efficiency and reducing both computing power and edge AI requirements.

We support all spectral imaging types, including snapshot HSI for geometrical accuracy and stereophotography, as well as pushbroom hyperspectral imaging with tunable light sources.

Our hyperspectral imaging technology exploits the full native image resolution of the image sensor. This allows you to select the required spatial resolution without limits.

You can use any image sensor with our hyperspectral imaging technology, providing a great degree of flexibility.

We offer universal hyperspectral imaging solutions in all wavelengths, from UV to Thermal IR.

Our spectral solutions can be applied to light sources, extending hyperspectral capabilities to your existing imaging systems. The light sources range from LEDs to super-continuous LASERs, enabling real-time classification over long distances or conveyor belts. Our solutions have demonstrated real-time classification at distances of over one kilometre.

Our hyperspectral technology is already integrated into award-winning commercial products and is mobile-camera-ready.

An open-source python interface allows you to build your own software proprietary layer.

The MEMS version of our hyperspectral solutions allows you to plan for a near future where hyperspectral cameras are as affordable as mobile cameras.

We have built a large and licensable IP portfolio with over 20 hyperspectral-related patents families.

Finland: an epicentre for hyperspectral imaging

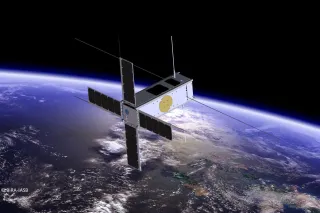

Finland, where we are based, is a hub for hyperspectral technology. Over several decades, VTT has been at the forefront of spectral innovations, from space exploration to handheld microspectrometers. Our hyperspectral technology is the world's first to be onboard nanosatellites.

Our leadership in the field is demonstrated by the number of successful spinoff companies VTT has generated, including:

Specim (acquired by Konica-Minolta): market leader in hyperspectral imaging cameras

Spectral Engines: best-in-class performance in handheld point spectrometers

Asqella (Now See-through-solutions): spectral terahertz imaging

VTT also invests IPR in companies like, for example, Kuva Space, a pioneer of Earth observation with a constellation of hyperspectral nanosatellites.

How to work with us

Tell us what you want to do, and we will figure out how to do it. No project is too small or too ambitious – we would love to hear from you. After the initial assessment, we might be able to offer some of the following options:

-

Customised partnership

Every research case is unique, and we’re happy to tailor our services to your needs. We’ll take you from idea to prototype without hassle.

-

Cooperative project

We frequently participate in research and development projects with multiple business partners and funding agencies. In cooperative projects the risk is split between multiple organisations, and everyone benefits from the results.

-

Our networks and ecosystems at your disposal

We are happy to put you in touch with the ideal sparring and development partner.

Note that we do not fabricate and sell products as such.

Experts behind the service

VTT’s team of experts knows how hyperspectral solutions and applications can be harnessed to benefit your business.

Contact us here!

Scientific publications

We have a large database of publications in our research portal Pure. Find peer reviewed publications related to hyperspectral technologies by clicking the button below.