Industrial circular economy and ecodesign

Through circular economy and ecodesign we enable significant improvement in resource efficiency on a sustainable basis. VTT helps industrial customers develop breakthrough circular materials, products and processes.

Key facts: industrial circular economy and ecodesign

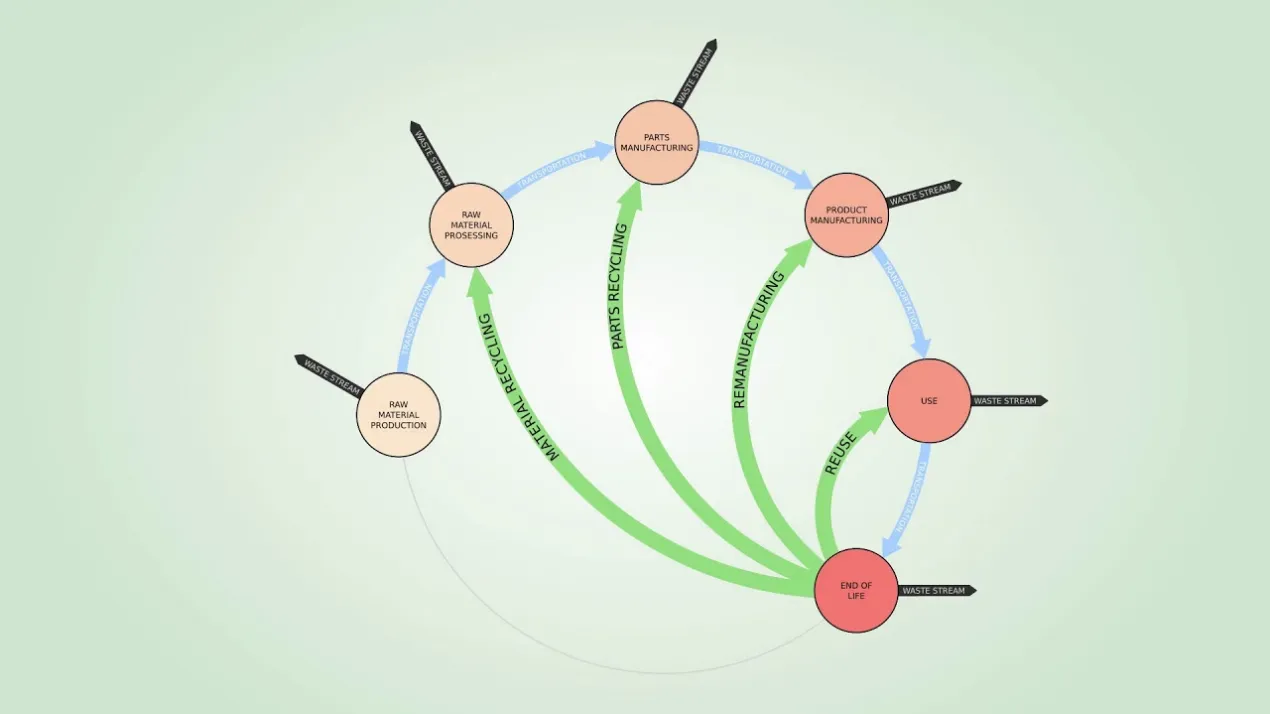

Closing, lengthening and redesigning the material loops are in the core of circular economy.

We have the capability to develop, demonstrate and deliver breakthrough circular materials, products and processes.

VTT has broad experience in helping customers solve their raw material challenges due to competent personnel and advanced facilities.

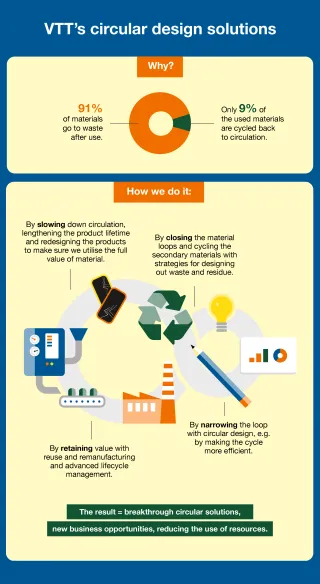

Our mission is to close the loop on the 91% of natural resources that currently go to waste. The natural resource base is finite and the availability of resources may be constrained by political or financial terms (e.g. critical raw materials). Transport for long distances increases the environmental footprint. Today, only 9% of the used raw materials are cycled back to the material loop. To ensure resource sufficiency, we need to redesign products, materials and processes to support circular economy.

Closing the loop on the 91% of natural resources that currently go to waste requires a completely new approach

VTT helps industrial customers with circular economy know-how, ecodesign of materials and products as well as closing, lengthening and redesigning the material loops. We have the capability to develop, demonstrate and deliver breakthrough circular solutions.

We also facilitate our customers to push their circular economy approaches and help them shift from resource- and product-intensive models towards data-driven and service-centric operation models. The aim is to open and create new business opportunities, while significantly reducing the use of natural resources.

Multi-disciplinary team at your service

At VTT, our strength is the multi-disciplinary knowledge-base and a versatile research infrastructure. The raw materials, such as minerals, ores and metals, biomass and fossil raw materials, are all very different with respect to chemical and physical characteristics. The scales of interest range from micro-level up to system-level, and therefore different viewpoints are necessary towardsthe realisation of their circular economy potential.

VTT has broad experience in helping customers to solve their raw material challenges of various types to meet stringent sustainability targets.

From solar panels to components from industrial side streams

Here are some examples of our past work we are proud of:

-

We have produced ultra-thin, light-weight and flexible electronic devices, e.g., solar cells, that are essentially environmentally sustainable.

-

Together with our partners, we have developed refractory ceramic components from steel industry side streams, slags.

-

Currently we research methods to make food and chemicals from CO2.

Join the group of open-minded pioneers of industrial circular economy and seize on the mission of 91%.

What VTT offers?

- Systemic approach for circular economy through value chain for maximising positive impact.

- Circular design of systems and materials for improved circularity and new business opportunities.

- Development of tailored and analysed data for broad understanding and knowledge, e.g. integration of economic, environmental and performance data.

- Criticality assessment of materials on economic and supply risks and substitution.

Competent personnel + advanced facilities = uniquely qualified support for our customers’ circular design challenges.

Contact us here!

Publications related to industrial circular economy and ecodesign

R2R-printed inverted OPV modules – towards arbitrary patterned designs

Read more

- Resource-efficient future cities

- Material design solutions for circular economy

- Digital tool platform enhances VTT’s role in collaborative circular design - bird’s eye view of design impacts

- Circularity and beyond: Benefiting from integrated life cycle assessment (LCA) and life cycle costing (LCC)

- Systemic change towards a circular economy and profitable business – but how?

Towards sustainable electronics

At VTT, our goal is to set a new standard for sustainability in the electronics industry and offer solutions that increase circularity at every stage of the electronics life cycle. Explore:

- Five ways to improve sustainability of electronics

- How to create new business from sustainable electronics?

- How to reduce electronics waste with sustainable printed electronics?