Smart industry

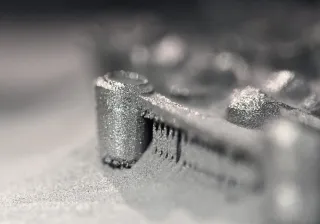

Digitalisation is transforming the industrial sector. In the future, people will work side by side with automation to provide a holistic service. VTT helps industrial businesses and technology developers to come up with new business models and technologies to promote smart industry.

What is it that will make the industrial sector smart in the future? It could be, for example, flexible and adaptable production facilities in which people work side by side with automation.

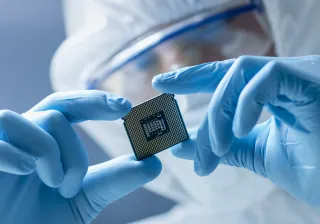

Robotics, flexible automation and artificial intelligence help industrial businesses to make their production processes more efficient and cut their costs.

Robotics, flexible automation and artificial intelligence help industrial businesses to make their production processes more efficient and cut their costs. The nature of business in the industrial sector is changing: industrial businesses no longer simply sell machinery and hardware but provide turnkey services.

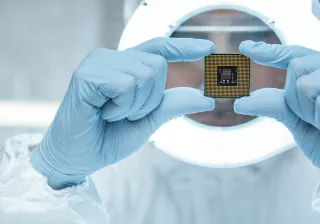

The radical digital transformation of industry also creates business opportunities for high-cost countries such as Finland. From the perspective of export, it is essential for Finland’s industrial sector to be one of the leading developers and adopters of new digital solutions and business models.

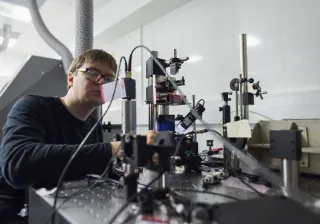

As a research and innovation partner, VTT is on the frontlines of developing new, smart industrial solutions. Our research focuses, in particular, on the major shifts of the industrial sector and the energy supply system. We develop business models and technologies side by side – through our cutting-edge multidisciplinary technological know-how.

Are you passionate about smart industry? Find out more about our services below or contact us to set up a bespoke partnership.