Photonics

Photonics harnesses the power of light. VTT's photonics research solves global and industrial challenges ranging from affordable healthcare and climate change to consumer electronics and autonomous vehicles.

Key facts

We cover applications with a broad photonic wavelength range from ultraviolet (UV) to mid-infrared (MIR)

Our technologies include small Si-based components, large-area printed devices and integrated systems.

VTT’s Silicon photonics integrated circuits are one of the most dense and efficient circuits in the world.

Photonics is a key enabling technology for applications in practically all areas of our modern society. The fiber optic network wraps around the globe and acts as a foundation for the internet and all the digital services, including the wireless communication networks and the internet of things. Everyday lighting solutions and displays used in phones and other digital devices are common photonics applications.

The Finnish photonics industry alone is currently worth more than 1 B€ and employs more than 4,000 people. The global photonics market was over 500 B€ in 2018 and it is expected to grow ~7% annually.

Silicon-based photonics technologies

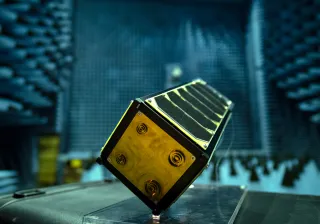

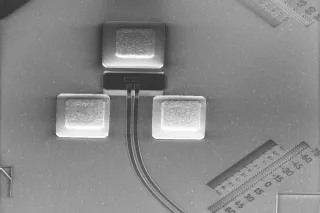

Silicon photonics is the new electronics. Silicon photonic integrated circuits (PIC) are the photonic equivalent of microprocessors. PICs can integrate hundreds of optical components, such as lasers, wavelength filters and photodetectors on a single silicon chip.

At VTT we develop PICs and chips which enable new components and systems for telecommunication, healthcare, autonomous vehicles and space applications. VTT’s PICs give the highest integration density based on patented design. Our expertise in the topic ranges from design, prototyping and integration to pilot manufacturing.

Everyday lighting solutions and displays used in phones and other digital devices are common photonics applications.

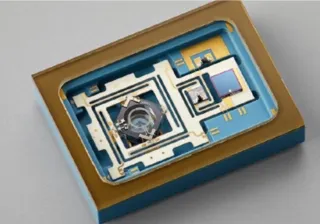

Various other photonic components can also be fabricated on small silicon chips using wafer processing methods common for microelectronics and micro electro-mechanical system (MEMS) industries. VTT’s Micronova clean room facility has strong R&D focus on photonics component development. Optical MEMS mirrors are developed for lidars that are to be used in autonomous vehicles, drones and robots. Fabry-Perot interferometer (FPI) microspectrometers with precisely tunable mirrors are used for various imaging and sensing applications. VTT’s award-winning and patented FPI technology is used in several commercial products, such as Vaisala's gas sensors, Revenio's skin-cancer detection product, Rikola's remote sensors and InnoPharmalabs' pharmaceutical hyperspectral imagers. One of VTT's many spin-offs, namely Spectral Engines, has brought FPI-based sensors to industrial, farming and consumer markets.

Large-area photonics technologies

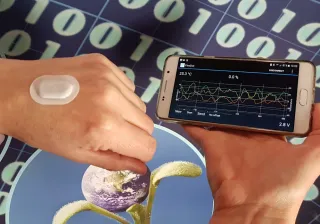

Large-area, roll-to-roll photonic systems produced on plastic foils can potentially create many new applications and business opportunities. The key benefits are twofold. Firstly, in certain application domains, the production volume is not counted as number of devices but more as how large an area can be covered with the photonic components.

On the other hand, photonic smart systems can also be sustainably disposable, for example in personalised diagnostics and well-being products. In these cases, credit card -sized products manufactured at very high volumes are needed to keep the product costs low.

VTT has extensively developed methods to produce both active and passive photonic components using printing methods that are used for light harvesting (solar cells), illumination (lighting and displays) and sensing applications. Our unique offering covers compatible component level production and integration of smart systems on roll-to-roll, flexible plastic foils. In PrintoCent facility, companies get easy access to new business development and pilot manufacturing resources for the introduction of printed and hybrid integrated photonic systems.

Related infrastructure

Instruments and systems

Photonic and optical instruments and machine-vision systems are often used in industrial settings, like medium and large factories. VTT has developed dozens of commercialised instruments that are currently in use in the most demanding, harsh process environments to monitor for example chemical composition, thickness of material and surface uniformity.

We have extensive knowhow on the development cycle of optical instruments, starting from defining measurement principles, designing of instruments, quick prototyping for testing feasibility in field conditions and then moving to final product development. The mission is to provide superior research and development services for both process measurement and control system suppliers and for industrial end users.

Video: What is photonics?