Sustainability and life cycle assessment

Sustainability assessment provides factual basis on strategic decision-making and stakeholder communication. Footprints support product development and help to identify reduction potential. The handprint approach provides a way to communicate about your positive impacts.

Key facts about sustainability and life cycle assessment

LCA methods

Indicators based on scientifically approved LCA methods help companies make the right decisions for product and process design

Carbon footprint

Carbon footprint enables low-carbon process and product design Carbon footprint consists of the GHG emissions emitted during a product life cycle

Handprint

Handprint is a new way of communicating your positive environmental impacts

Sustainability is the key driver behind the current transformation to circular and bio economy towards United Nations Sustainable Development Goals. The urgency of climate change is motivating individuals, companies and their customers to move towards sustainable lifestyles, products and production. All leading-edge companies today share the pain and want to do the right thing - but what are the best strategies and choices, and their impacts? Will we meet the new customer demand and be compliant with future targets and regulations? How do we credibly communicate our sustainability benefits to our key customers?

Not all business choices that increase recycling or convert to biomaterials are sustainable

A well designed sustainability strategy, based on fact-based reasoning, provides a sound and future-looking foundation for making business. We also need improved processes, technologies and eco design practices to strive in the market. Understanding sustainability factors early on in the R&D cycle will help de-risk the development project.

Base company sustainability strategies on facts

LCA (life cycle assessment), carbon and water footprints (ISO 14067 and 14046), environmental footprints (PEF), handprints and other lifecycle thinking -based tools provide a systematic, impartial and globally accepted method to assess impacts of products and services.

Lifecycle methods take into account a product’s entire lifespan, from raw material extraction through materials processing, manufacturing, distribution, use, repair and maintenance, and eventual disposal or recycling. The comprehensive methodology enables a full product lifetime eco design and new circular business models. Our development of the handprint approach and other sustainability indicators continues.

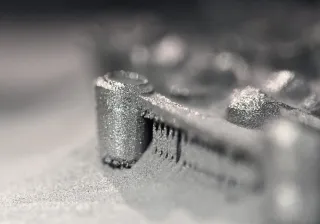

Towards sustainable electronics

At VTT, our goal is to set a new standard for sustainability in the electronics industry and offer solutions that increase circularity at every stage of the electronics life cycle.

Proven results based on top expertise

VTT has provided sustainability and life cycle assessment expertise since 1990. Our experienced scientist team works daily with manufacturing, process, chemical, energy industries and food applications, with the support of our in-house technology experts, to bring industrial relevance.

VTT is a recognized stakeholder in the EU expertise groups and the leader of the national International Standardisation (ISO) mirror group in Finland.

We’d love to work with you on

- Communicating efficiently to customers

- Basing sustainability strategies on facts and science

- Comparing alternative raw materials, technologies and business solutions

- Designing R&D initiatives to support sustainability targets

- Ensuring and planning for compliance with future regulations

- Supporting political decision-making