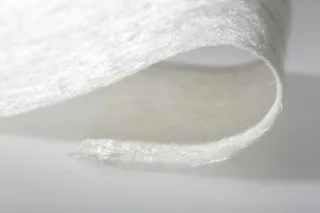

To reduce the textile industry’s environmental impact, renewable raw materials and more recycling is needed. At VTT, we innovate sustainable fabrics and better ways of recycling fibres with our customers.

Key facts

Sustainable textiles are the answer to shifting consumer preferences and tightening environmental regulation.

We can help you develop manufacturing processes for sustainable fibres and nonwoven fabrics.

Better recyclability improves the sustainability of the whole textile industry.

Jaakko Kuusisaari